The Buckeye State is officially green, and the opportunity is unprecedented. Ohio’s adult-use cannabis market represents one of the most significant business opportunities in recent state history, with projections indicating substantial revenue potential for early movers who understand the regulatory landscape. However, success in this burgeoning market requires more than just quality products – it demands meticulous attention to compliance, particularly when it comes to packaging requirements that can make or break a cannabis business.

Packaging is not just a container; it’s a crucial element for compliance, branding, and product integrity that serves as the first line of defense against regulatory violations and the primary touchpoint between businesses and consumers. The challenge lies in Ohio’s evolving regulatory framework, where non-compliance can result in hefty fines, license suspensions, or complete business shutdowns. The stakes couldn’t be higher, as regulatory authorities conduct both announced and unannounced inspections to ensure adherence to packaging standards.

This comprehensive guide provides cannabis cultivators, processors, manufacturers, dispensaries, brands, and entrepreneurs with definitive insights into navigating Ohio’s packaging landscape. From understanding child-resistant requirements to mastering product-specific considerations, this post covers every aspect of compliant packaging while exploring opportunities to leverage packaging for competitive advantage. Ghettopac stands ready as your trusted partner in this journey, offering expertise and solutions that ensure both compliance and market success in Ohio’s dynamic cannabis environment.

Understanding Ohio’s Regulatory Landscape for Cannabis

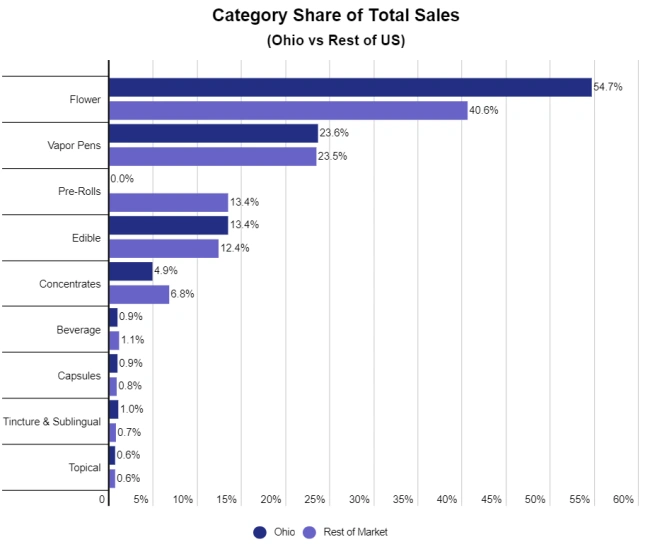

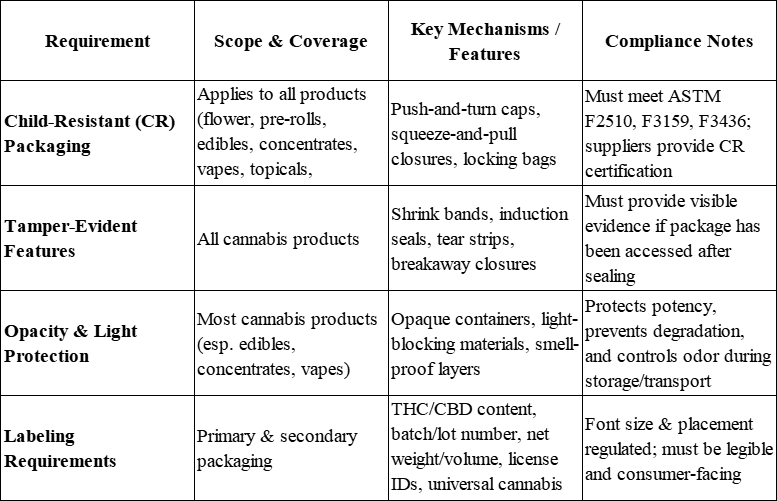

Ohio’s path to cannabis legalization began with medical cannabis in 2016 through House Bill 523, establishing the Ohio Medical Cannabis Control Program (OMMCP). The transformative moment came on November 7, 2023, when voters approved Issue 2, legalizing adult-use cannabis with implementation beginning December 7, 2023. This ballot initiative created the Division of Cannabis Control (DCC) within the Ohio Department of Commerce, consolidating regulatory oversight that was previously divided among multiple state agencies.

The current regulatory structure represents a significant evolution from the original medical-only framework. Prior to the DCC’s establishment, oversight was shared between the Ohio Department of Commerce (cultivators, processors, testing laboratories), the Ohio Board of Pharmacy (dispensaries, patient registration), and the State Medical Board of Ohio (physician certifications). This consolidation under the DCC has streamlined operations while maintaining rigorous compliance standards that businesses must navigate carefully.

Packaging sits at the center of Ohio’s regulatory framework for compelling reasons. Public safety considerations mandate child-resistant packaging to prevent accidental ingestion, while comprehensive labeling requirements ensure consumers receive accurate information about potency, ingredients, and proper dosing. Additionally, packaging serves as a critical tool in preventing illicit market diversion by providing robust tracking mechanisms and tamper-evident features that maintain product integrity throughout the supply chain.

The regulatory framework operates under Ohio Revised Code Chapter 3780 and detailed Ohio Administrative Code provisions that govern specific packaging requirements for cultivators, processors, and dispensaries. These rules are dynamic and subject to regular updates as the market matures and regulators gain operational experience. As of January 30, 2025, the DCC had issued 131 dual-use dispensary certificates of operation, demonstrating the rapid market development that requires businesses to stay current with evolving packaging standards.

Core Packaging Requirements Across All Cannabis Products in Ohio

Child-Resistant Packaging Standards

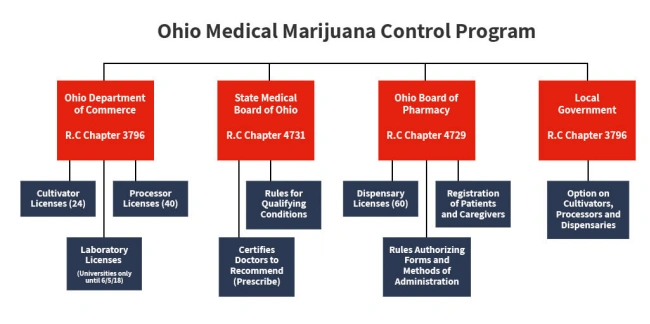

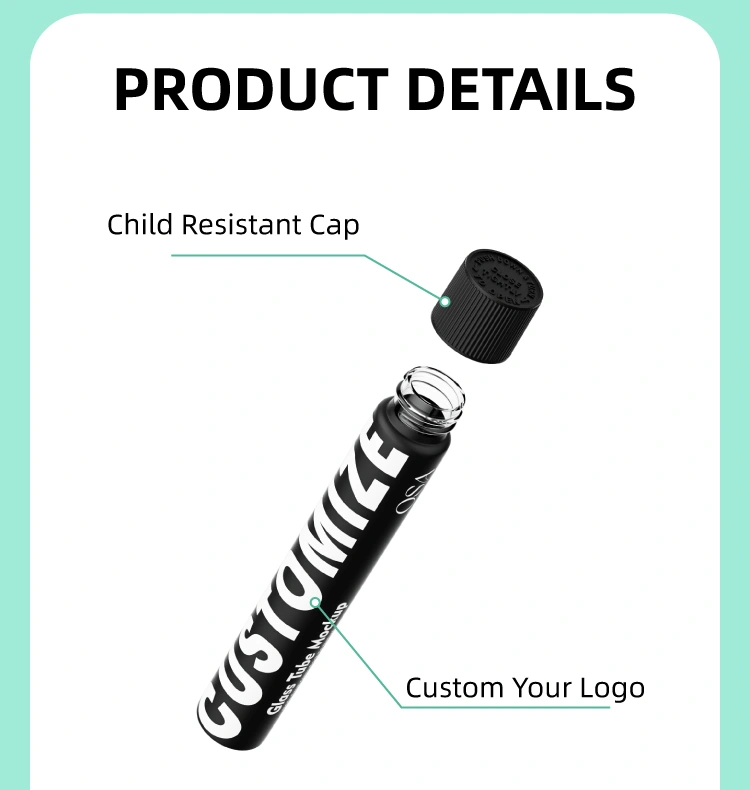

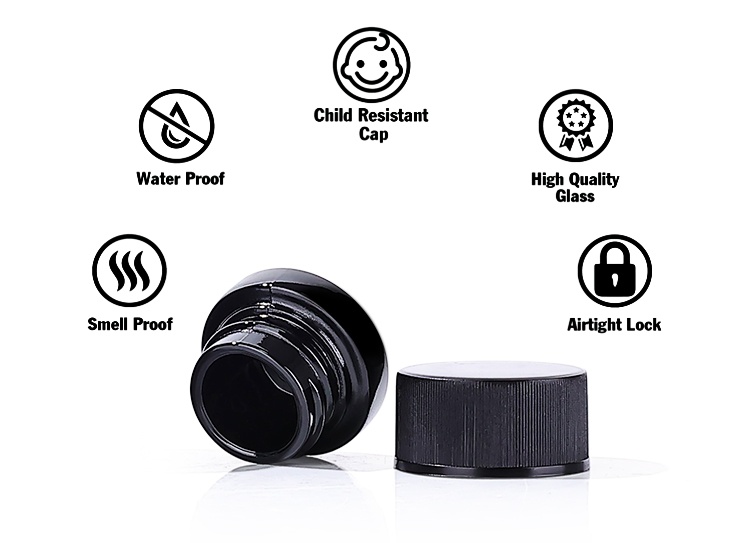

Child-resistant (CR) packaging forms the foundation of Ohio’s safety-first approach to cannabis regulation. Ohio adheres to federal standards including ASTM F2510, F3159, and F3436, which define child-resistant mechanisms that are difficult for children under five years old to open while remaining accessible to adults. All cannabis products sold in Ohio must utilize certified CR packaging, with testing and certification documentation required to verify compliance.

The scope of CR requirements extends to virtually all cannabis products, including flower, pre-rolls, edibles, concentrates, vape products, topicals, and tinctures. Common CR mechanisms include push-and-turn caps, squeeze-and-pull closures, and specialized locking bags that meet certification standards. Businesses must ensure their packaging suppliers provide verifiable CR certification documentation, as regulators may request proof during inspections.

Tamper-Evident Features

Tamper-evident packaging serves dual purposes: protecting consumers from compromised products and maintaining product integrity throughout the supply chain. Required tamper-evident features include shrink bands, induction seals, tear strips, or other mechanisms that provide visible evidence of package tampering. These features must be applied in a manner that makes it obvious to consumers if the product has been accessed after initial packaging.

Opacity and Light Protection Requirements

Ohio mandates opaque or light-resistant packaging for most cannabis products to protect against degradation caused by light exposure. This requirement preserves product potency and quality while containing odors that might attract unwanted attention. Packaging materials must effectively block light transmission while maintaining structural integrity during storage and transportation.

Labeling Requirements

Ohio’s labeling requirements represent some of the most detailed in the cannabis industry, reflecting the state’s commitment to consumer protection and regulatory compliance. Mandatory information includes product identity and type, precise THC and CBD content measurements (both per dose and per package), net weight or volume, and unique batch or lot numbers for tracking purposes.

Additional required elements include manufacturer/processor name and license identification numbers, cultivator name and license identification, harvest or production dates with expiration dates, Ohio’s universal cannabis symbol, and government-mandated warning statements such as “Keep out of reach of children” and “For medical use only”. For processed products like edibles and topicals, complete ingredients lists and storage instructions must be prominently displayed.

Font size and legibility requirements ensure critical information remains accessible to consumers, while placement specifications dictate where labels must appear on both primary packaging (containing the product) and secondary packaging (exit bags or outer containers). These requirements balance consumer safety with practical business operations, requiring careful coordination between packaging design and regulatory compliance.

Product-Specific Packaging Considerations in Ohio

Cannabis Flower Packaging

Cannabis flower packaging in Ohio requires careful consideration of preservation, compliance, and consumer experience. Acceptable packaging types include mylar bags, glass jars, plastic containers, and metal tins, all of which must incorporate child-resistant closures and tamper-evident features. Opacity or light-resistance is mandatory to protect cannabinoids and terpenes from degradation.

Preservation considerations extend beyond basic protection to include humidity control through compatible humidity packs and airtight sealing mechanisms that maintain freshness. Ohio’s flower packaging must accommodate strain-specific labeling that includes strain names, comprehensive cannabinoid profiles, and terpene information where available. Weight accuracy becomes crucial as Ohio enforces strict measurement standards with regulatory oversight of packaging processes.

Pre-Roll Packaging Solutions

Pre-roll packaging presents unique challenges in balancing protection, compliance, and convenience. Child-resistant tubes represent the most common solution, available in various sizes to accommodate different pre-roll dimensions and quantities. Multi-pack boxes with individual CR compartments offer another compliant option for businesses selling multiple pre-rolls as single transactions.

Protection requirements focus on preventing crushing during transport and maintaining product freshness through proper sealing. Ohio regulations require clear labeling of quantity and individual pre-roll weights, creating transparency for consumers while supporting regulatory compliance. Tamper-evident features must be incorporated without compromising the structural integrity needed to protect delicate pre-roll products.

Edibles Packaging Compliance

Edibles packaging receives the highest regulatory scrutiny in Ohio due to their appeal to minors and potential for accidental ingestion. Child-resistant requirements often necessitate dual-layer packaging systems where individual servings require CR access even within larger CR containers. Ohio enforces strict dose limits, typically requiring clear labeling of THC content per serving and per package with maximum limits defined by regulatory authorities.

Appearance restrictions prohibit shapes, colors, or designs that might appeal to children, requiring businesses to develop adult-oriented aesthetics that comply with regulatory standards while maintaining market appeal. Serving size and dosing information must be clearly displayed with precise measurements and consumption guidance. The complexity of edibles packaging often requires specialized suppliers with deep understanding of both food safety and cannabis regulations.

Concentrate and Vape Product Packaging

Concentrates and vape products require packaging that addresses product compatibility, child resistance, and tamper evidence. Packaging materials must be compatible with concentrated cannabis products, ensuring no leaching or contamination occurs during storage. Child-resistant mechanisms must function reliably despite potential product residue, while tamper-evident features must remain effective throughout the product lifecycle.

Labeling specifics for concentrates include potency measurements, consumption method guidance, and hardware information for vape products. Packaging must accommodate various concentrate consistencies from oils to waxes while maintaining regulatory compliance and product integrity.

Topicals and Tinctures Packaging

Topicals and tinctures present distinct packaging challenges based on their intended use and consumption methods. Child-resistant requirements apply primarily to ingestible tinctures, while topical products may have modified requirements based on their external application. All products require tamper-evident features and comprehensive labeling that includes application instructions and complete ingredient lists.

Packaging must accommodate liquid products without leakage while maintaining child-resistant functionality over repeated use cycles. Clear labeling of THC content, application methods, and ingredients ensures consumer safety and regulatory compliance.

Beyond Compliance: Leveraging Packaging for Brand Success in Ohio’s Competitive Market

Ohio’s “Green Rush” creates unprecedented opportunities for brands that understand how to leverage packaging beyond mere compliance. Standing out in this rapidly expanding market requires strategic thinking about how packaging communicates brand values, builds consumer trust, and creates memorable experiences that drive customer loyalty.

Branding through packaging becomes particularly important as Ohio’s market matures and consumers develop preferences based on more than just price and potency. Market research suggests Ohio consumers respond positively to packaging that conveys quality, safety, and local pride, creating opportunities for brands to differentiate through thoughtful design choices.

Design and Aesthetic Considerations

Ohio’s cannabis consumers demonstrate preferences for packaging that balances sophistication with accessibility, rejecting overly clinical appearances while demanding professional presentation. Material choices between glass and plastic often communicate quality positioning, with glass containers suggesting premium products and plastic offering practical convenience. Premium finishes such as soft-touch coatings or metallic accents can elevate brand perception within regulatory constraints.

Color psychology plays a significant role in consumer decision-making, with earth tones and natural colors resonating with health-conscious consumers while bold colors can attract attention in crowded dispensary displays. Typography choices must balance readability requirements with brand personality, ensuring compliance with font size regulations while maintaining consistent brand voice across product lines.

Sustainability as Competitive Advantage

Growing consumer demand for eco-friendly packaging creates opportunities for forward-thinking Ohio cannabis brands. Post-consumer recycled (PCR) materials, biodegradable options, and recyclable packaging solutions can differentiate brands while appealing to environmentally conscious consumers. Sustainable packaging messaging can become a powerful marketing tool, particularly among younger demographics who prioritize environmental responsibility.

However, sustainability initiatives must be carefully balanced with regulatory requirements, as child-resistant and tamper-evident features can limit sustainable material options. Successful brands work closely with packaging suppliers to identify solutions that meet both environmental goals and compliance mandates.

User Experience Optimization

Balancing Child-Resistance with Adult Accessibility

User experience optimization in Ohio cannabis packaging presents a sophisticated engineering challenge that requires balancing stringent safety requirements with practical usability for legitimate adult consumers. Research indicates that approximately 50% of cannabis users experience difficulty opening child-resistant containers, highlighting the critical need for thoughtful design that maintains compliance while respecting user convenience. This challenge becomes particularly acute for elderly consumers and individuals with arthritis or other dexterity limitations who may struggle with traditional push-and-turn or squeeze-and-pull mechanisms.

Effective solutions incorporate ergonomic considerations into child-resistant designs, such as larger grip surfaces, textured areas for better handling, and mechanisms that require adult-level coordination rather than excessive force. Some innovative approaches include magnetic locking systems that are intuitive for adults but confusing for children, or dual-motion requirements that combine fine motor skills with sequential actions. These designs demonstrate that child-resistance doesn’t necessitate user frustration when proper engineering principles are applied.

Resealable Functionality for Extended Use Patterns

Ohio’s adult-use market recognizes that cannabis consumption often occurs over extended periods, with many consumers using products intermittently over days or weeks rather than in single sessions. Resealable packaging must therefore maintain product integrity through multiple opening and closing cycles while preserving freshness, potency, and flavor profiles that degrade with exposure to air, light, and moisture.

Advanced resealable solutions incorporate multiple sealing mechanisms, such as primary airtight seals for product preservation combined with secondary child-resistant closures for safety compliance. Some packages feature graduated opening systems where consumers can access portions of the product while keeping the remainder sealed, particularly valuable for flower products where exposure to air can significantly impact quality. Humidity control integration, through compatible humidity pack compartments, further extends product viability while maintaining the convenience of resealable access.

The consumption pattern consideration extends beyond simple freshness to accommodate different usage scenarios. Microdosing consumers may access small amounts frequently, requiring packaging that maintains seal integrity through numerous interactions. Conversely, occasional users need packaging that preserves products through extended storage periods, potentially months, without degradation.

Information Hierarchy and Visual Design

Ohio’s comprehensive labeling requirements create substantial information density on cannabis packaging, making intuitive information hierarchy essential for positive user experience. Effective packaging design employs visual hierarchy principles to guide consumer attention to the most critical information first—product type, potency levels, and safety warnings—while making secondary information accessible without overwhelming the primary visual experience.

Color coding systems can help consumers quickly identify product categories or potency levels, while consistent typography hierarchies ensure readability across different package sizes and formats. The challenge lies in presenting legally mandated information including THC/CBD content, batch numbers, license information, and regulatory warnings in ways that inform rather than intimidate consumers. Strategic use of white space, logical information grouping, and intuitive iconography can transform complex regulatory requirements into user-friendly interfaces.

Font size considerations become particularly important for older consumers, who represent a significant portion of Ohio’s medical cannabis market. Research indicates that 78% of cannabis users over 45 experience difficulty reading standard package labels, with 75% expressing preference for larger font options. Successful packaging accommodates these needs through scalable text sizes, high-contrast color combinations, and clear visual separation between different information categories.

Digital Integration and Enhanced Information Access

QR codes represent a powerful bridge between physical packaging constraints and comprehensive consumer education, allowing Ohio cannabis businesses to provide extensive information without overwhelming package design. These digital touchpoints can link to detailed laboratory results, comprehensive dosing guidelines, consumption method instructions, and even personalized consumption tracking tools that help consumers optimize their experience over time.

Beyond basic product information, QR codes can provide access to educational content about strain genetics, cultivation methods, expected effects, and potential interaction warnings that exceed what’s possible through traditional labeling. This approach particularly benefits new consumers who may need extensive guidance while allowing experienced users to access advanced information as desired.

Integration with state tracking systems through QR codes also enables consumers to verify product authenticity and access complete supply chain information, building trust and transparency that differentiates legal market products from illicit alternatives. Some advanced implementations include batch-specific information that consumers can access to understand the particular characteristics of their specific purchase, including harvest dates, curing methods, and quality control test results.

The digital integration strategy must consider accessibility across different demographic groups, ensuring that enhanced features supplement rather than replace essential physical packaging information. This approach acknowledges that while some consumers embrace digital enhancement, others prefer traditional information presentation methods, requiring packaging solutions that serve both preferences effectively.

Common Packaging Pitfalls and How to Avoid Them in Ohio

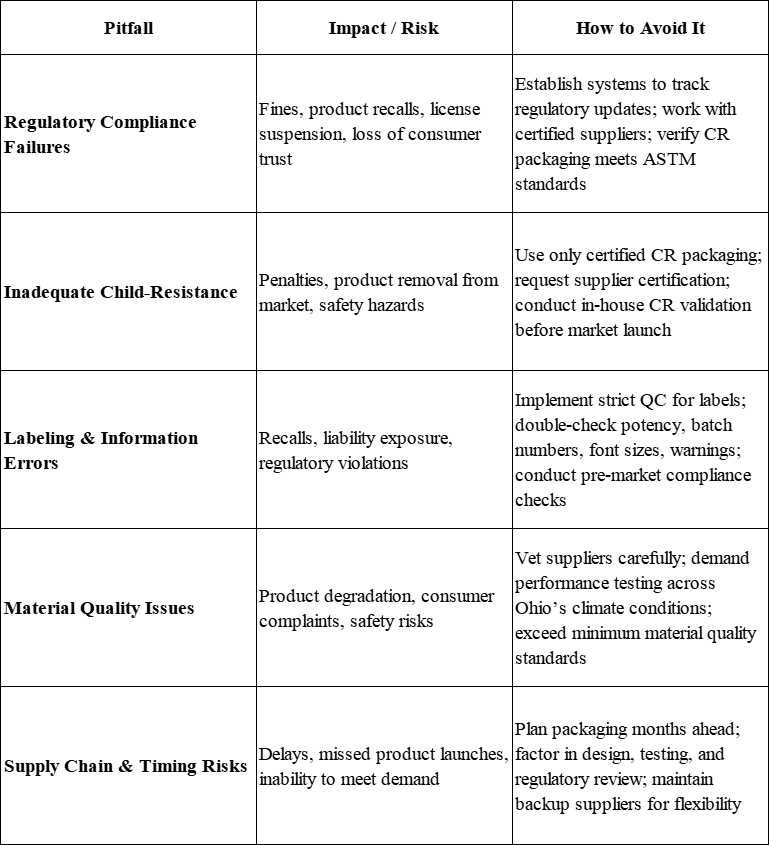

Regulatory Compliance Failures

The most common and costly mistake Ohio cannabis businesses make is failing to stay current with evolving regulations. The DCC regularly updates packaging requirements as market conditions change and regulatory experience grows. Businesses must establish systems for monitoring regulatory updates and ensuring packaging suppliers remain informed about current requirements.

Inadequate child-resistance represents another frequent compliance failure, often resulting from using non-certified packaging or mechanisms that can be easily defeated by determined children. Ohio regulators take child safety seriously, conducting thorough inspections and imposing significant penalties for non-compliant packaging.

Labeling and Information Accuracy

Incorrect labeling creates liability exposure and regulatory violations that can jeopardize business operations. Missing required information, incorrect font sizes, or inaccurate potency measurements can result in product recalls, fines, or license suspensions. Businesses must implement quality control systems that verify label accuracy before products reach consumers.

Material Quality and Supply Chain Issues

Poor quality packaging materials can lead to product degradation, customer complaints, and potential safety hazards. Ohio’s climate variations require packaging that performs consistently across different temperature and humidity conditions. Businesses must carefully vet packaging suppliers and establish quality standards that exceed minimum regulatory requirements.

Last-minute packaging sourcing represents a critical business risk, as custom packaging often requires weeks or months for design, testing, and production. Successful businesses plan packaging needs well in advance, factoring in lead times for regulatory review and design iterations that may be necessary to achieve compliance and brand objectives.

Partnering for Success: How Ghettopac Can Help Ohio Cannabis Businesses

Navigating Ohio’s complex packaging landscape requires expertise, experience, and reliable partnerships that ensure both compliance and competitive advantage. Ghettopac, Jarsking’s specialized cannabis packaging line, brings deep understanding of Ohio’s regulatory requirements combined with extensive experience serving cannabis businesses across multiple markets, providing the knowledge and solutions Ohio businesses need to succeed in the Buckeye State’s rapidly expanding market.

As Ohio’s Division of Cannabis Control continues refining regulations and conducting both announced and unannounced inspections, Ghettopac’s compliance expertise encompasses not just current Ohio requirements under Ohio Revised Code Chapter 3780 and related Administrative Code provisions, but also emerging trends and regulatory developments that may impact future packaging needs. This forward-thinking approach helps businesses avoid costly packaging changes while positioning them for long-term success as Ohio’s market matures from its current 131 dual-use dispensary certificates to potentially hundreds more locations.

Ghettopac’s comprehensive product portfolio, developed specifically for cannabis industry needs, includes compliant packaging solutions for every product category regulated by Ohio’s DCC. From child-resistant flower containers meeting ASTM standards to specialized edibles packaging that addresses Ohio’s strict 10 milligrams per serving and 100 milligrams per package THC limits, each solution incorporates the mandatory tamper-evident features and opacity requirements demanded by Ohio regulations. Pre-roll tubes, concentrate containers, and tincture packaging all feature the dual-layer protection systems often required for Ohio compliance, while maintaining the aesthetic appeal necessary for competitive dispensary environments.

Jarsking’s design services, delivered through the Ghettopac line, help Ohio brands create distinctive packaging that incorporates the mandatory DCC Packaging Seal and required warning statements while standing out in crowded dispensary environments. Rather than offering generic solutions, Ghettopac’s consultative approach means working closely with each Ohio business to understand their unique needs, target customers, and brand objectives within the constraints of Ohio’s evolving regulatory framework.

Supply chain reliability becomes crucial as Ohio’s market expands beyond its current operational base, with new adult-use licenses potentially being allocated beginning two years from initial issuance based on market factors. Ghettopac’s established supply chain and inventory management systems, backed by Jarsking’s manufacturing capabilities, ensure timely delivery of high-quality packaging materials that meet Ohio’s specific requirements for child-resistance, tamper-evidence, and comprehensive labeling, supporting business growth without the operational disruptions that can result from packaging compliance failures.

Conclusion

Ohio’s cannabis market represents extraordinary opportunity for businesses that understand the critical role of compliant and effective packaging in building successful operations. From child-resistant requirements and tamper-evident features to product-specific considerations and branding opportunities, packaging touches every aspect of cannabis business success in the Buckeye State.

The regulatory landscape will continue evolving as Ohio’s market matures, requiring businesses to maintain vigilance and adaptability in their packaging approaches. Success demands more than minimum compliance – it requires strategic thinking about how packaging can differentiate brands, build customer trust, and support long-term business growth.

Partnership with experienced packaging providers like Ghettopac ensures businesses can focus on their core competencies while maintaining confidence in their packaging compliance and brand presentation. As Ohio’s Green Rush continues, the businesses that thrive will be those that recognize packaging as both a regulatory requirement and a competitive advantage, investing in solutions that serve both compliance and customer experience objectives.

The opportunity in Ohio is substantial, but it requires preparation, expertise, and commitment to excellence in every aspect of cannabis business operations. With proper packaging strategies and reliable partnerships, Ohio cannabis businesses can build the foundation for sustained success in one of America’s most promising cannabis markets.