Ghettopac provides hybrid one-stop packaging solutions to Support the cannabis industry

At Gettopac, we understand the unique challenges of the cannabis market. Our expertise combines regulatory knowledge, creative design, and sustainable practices to deliver packaging that protects your products and elevates your brand.

Our strength lies in our hybrid supply chain, which strategically combines owned manufacturing facilities with trusted partner networks to ensure complete control over quality and production timelines.

-

Owned Manufacturing Facilities – We operate our own glassware manufacturing facilities producing custom jars and specialty containers, dedicated post-processing plants offering premium finishing options (frosting, coloring, electroplating), and in-house plastic manufacturing for child-resistant containers and custom molded solutions.

-

Strategic Regional Production – By strategically situating our production hubs near essential material resources, we effectively reduce shipping times and logistical expenses, ensuring seamless production continuity.

-

Production Flexibility & Compliance – Our direct control over material sourcing and manufacturing processes ensures regulatory compliance while enabling rapid scaling between small-batch specialty runs and high-volume orders, accommodating businesses of all sizes with consistent quality.

-

Dedicated Innovation Team – Our in-house team of packaging engineers and designers continuously researches emerging materials, structural designs, and finishing techniques to create cannabis packaging that combines functionality with powerful brand expression.

-

Consumer-Centered Approach – We conduct extensive user testing to ensure our packaging designs enhance consumer experience through intuitive opening mechanisms, freshness preservation, and shelf appeal while maintaining compliance requirements.

-

Customization Capabilities – From concept sketches to production-ready designs, our development process focuses on creating distinctive packaging that differentiates your products while optimizing production efficiency and material usage.

-

Cannabis-Specific Expertise – With years dedicated exclusively to cannabis packaging, we understand the unique requirements for different product categories—from moisture control for flower to UV protection for concentrates and temperature stability for edibles.

-

Regulatory Navigation – Our extensive experience across multiple cannabis markets gives us uncommon insight into compliance challenges, helping clients avoid costly redesigns and ensuring smooth product launches in new jurisdictions.

-

Industry Insights – Our knowledge in the cannabis supply chain give us unique perspective on emerging trends, consumer preferences, and retailer requirements that inform our packaging innovations.

-

Integrated Service Model – From brand design and packaging development to manufacturing and logistics, our comprehensive approach eliminates the complexity of coordinating multiple vendors while ensuring consistency across your product line.

-

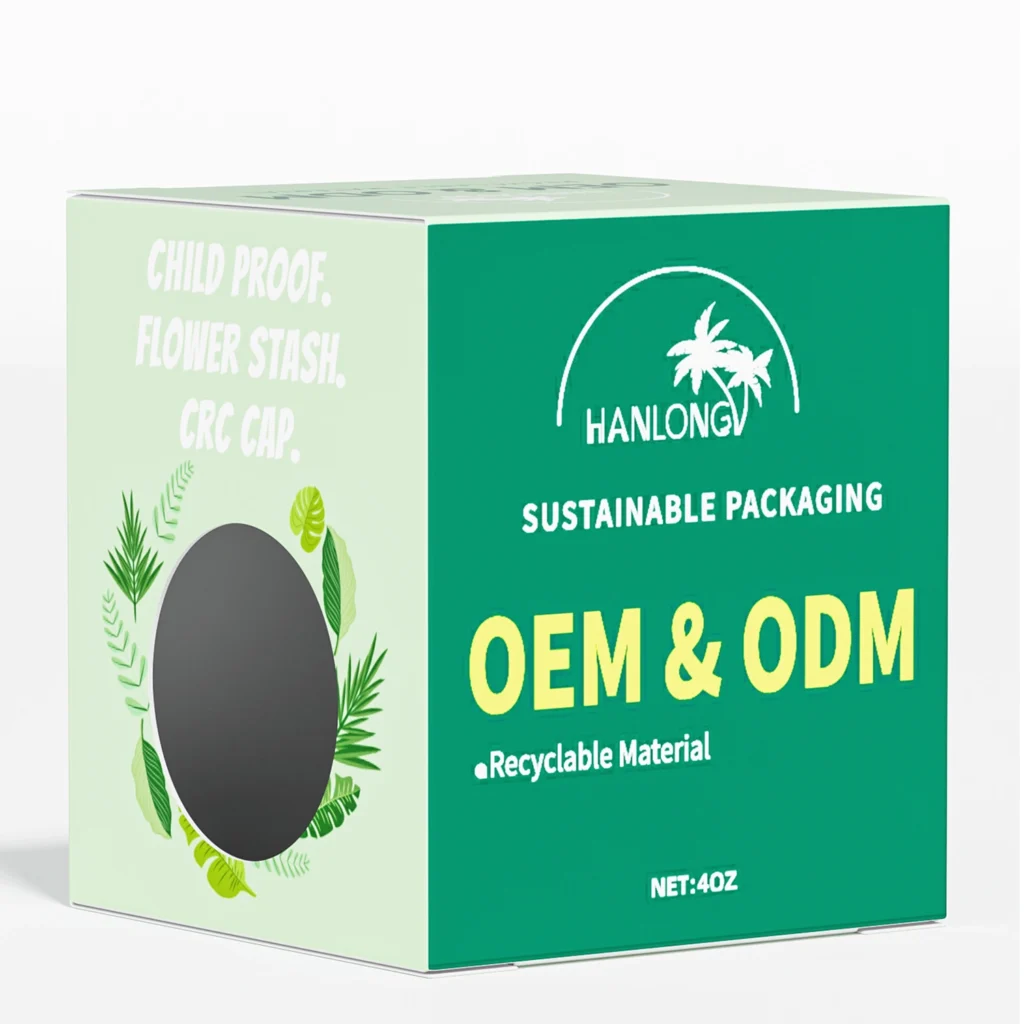

OEM & ODM Manufacturing – We offer both original equipment manufacturing and original design manufacturing services, allowing you to either bring your designs to life or leverage our expertise to develop proprietary packaging solutions.

-

Streamlined Project Management – A dedicated project manager guides you through the entire process, providing transparent communication, realistic timelines, and responsive service that simplifies packaging procurement.

-

Brand-Aligned Design – We develop packaging that authentically communicates your brand story and values through thoughtful material selection, structural design, and finishing techniques that resonate with your target audience.

-

Tailored Functionality – Each packaging solution is engineered to meet specific product requirements while providing optimal protection, user convenience, and shelf presence in increasingly competitive dispensary environments.

-

Scalable Options – Whether you’re launching a boutique brand or expanding a major product line, we offer customization options at every price point and certain production volume to ensure the right balance of distinction and cost-effectiveness.

-

Comprehensive Testing Protocols – We subject all packaging components to rigorous testing for child-resistance, material safety, barrier properties, and structural integrity to ensure consistent performance under real-world conditions.

-

Production Monitoring – Our quality control team inspects samples throughout production runs, verifying specifications for color accuracy, structural consistency, and finish quality to prevent issues before they affect your products.

-

Material Certification – We provide full documentation of material safety and compliance testing, ensuring all components meet or exceed regulatory requirements for food-grade materials and consumer safety standards.

-

Proactive Regulatory Monitoring – Our team tracks evolving cannabis packaging regulations across all active markets, anticipating changes and adapting designs to meet emerging requirements before they become mandatory.

-

Documentation & Certification – We maintain comprehensive records of all compliance testing and certification for child-resistant mechanisms, warning symbols, and required packaging features, simplifying audit preparation for our clients.

-

Market-Specific Solutions – Our packaging is engineered to address varying requirements across different jurisdictions, including state-specific warning symbols, opacity standards, and child-resistant certification levels.

Packaging for All Marijuana Products

Flower Jars

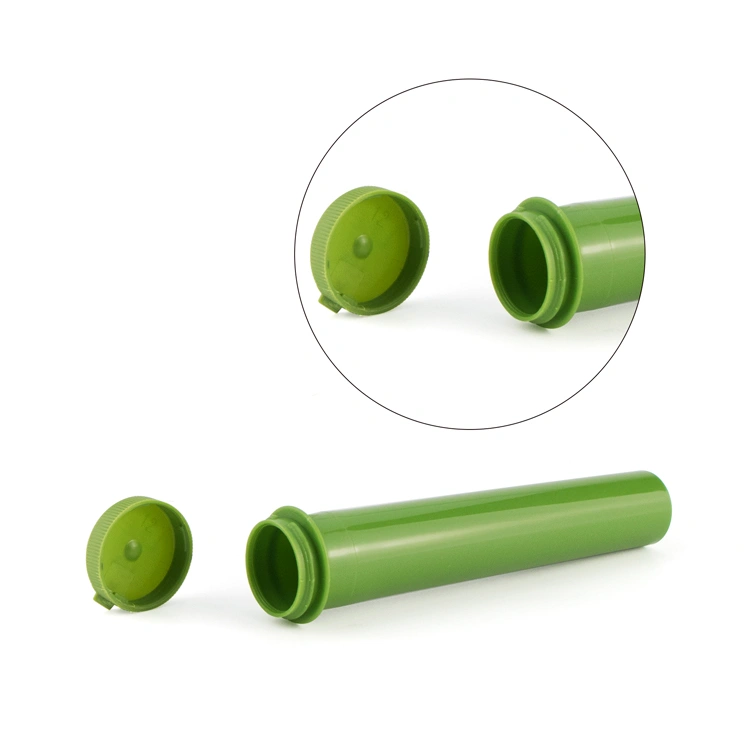

Pre-Roll Tubes

Concentrate Jars

Tincture Dropper Bottles

Pop Top Bottles

Mylar Pouches

Tin Containers

Rolling Trays

Medicine Bottles

Ampoules

Boston Bottles

Paper Boxes

Can’t Find The One That Hits Just Right?

No Worries, We Got You! 😎

We provide a wide range of customized packaging solutions for marijuana and pharmaceutical products. If you can’t find the packaging you need or have ideas for creating containers that reflect your brand’s identity, our sales team is here to help bring your vision to life.

Stand Out & Stand Legal

Distinctive Branding within Compliance Boundaries

Premium finishing techniques transform ordinary packaging into powerful brand assets that capture consumer attention and communicate quality. In the competitive cannabis market, where 65% of purchasing decisions occur at the point of sale, distinctive finishes create crucial differentiation that drives consumer selection and justifies premium pricing.

-

Silkscreen & Digital Printing – High-resolution CMYK/Pantone color matching ensures brand consistency, while precision silkscreening is ideal for logos and simple designs with less than four colors. Digital printing Offers high-resolution graphics and vibrant colors

-

Surface Enhancements – Color coating, electroplating, and soft-touch applications create distinctive tactile experiences that elevate perceived value

-

Specialty Techniques – Hot-stamping with metallic/holographic foils, selective spot UV treatments, and raised tactile embossing create visual highlights that draw attention to key brand elements

Distinctive packaging structures create immediate brand recognition and functional differentiation that standard containers cannot achieve. Unique structural designs create powerful visual and tactile memory triggers while addressing practical challenges like child-resistance, freshness preservation, and user convenience.

-

Proprietary Mechanisms – Custom child-resistant designs maintain regulatory compliance while offering intuitive adult use, balancing safety requirements with accessibility

-

Brand-Defining Silhouettes – Custom molds create distinctive container shapes and closure systems that become signature elements of your brand identity

-

User-Centered Engineering – Ergonomic features enhance consumer experience through improved grip, intuitive opening mechanisms, and specialized dispensing systems for concentrates and tinctures

-

Functional Innovation – Patented closure systems improve product freshness and prevent leakage while creating distinctive interaction points that reinforce brand recognition

-

Multi-Product Solutions – Specialized designs accommodate product families with consistent visual language across different consumption formats

Material selection communicates product quality and brand values while providing appropriate protection for cannabis products. Consumers judge product quality based on packaging materials, with premium materials justifying higher price points and influencing perceived efficacy of the contents.

-

Premium Glass Options – Standard and violet glass containers provide superior barrier properties while communicating quality, with specialized violet glass offering enhanced UV protection for light-sensitive products

-

Functional Plastics – Food-grade, BPA-free plastic options balance durability with cost-effectiveness while offering child-resistant features and recyclability

-

Metal Distinctions – Tin and aluminum containers provide excellent protection against light, moisture, and oxygen while creating premium tactile experiences through embossing and texture variations

-

Flexible Solutions – Custom Mylar pouches combine barrier protection with cost-effective branding through high-resolution printing and child-resistant closure options

Strategic color selection creates powerful psychological associations that define brand positioning and influence consumer perception. Research shows that color increases brand recognition by up to 80% and drives purchasing decisions.

-

Strategic Color Psychology – Consultation services help select palettes that reinforce specific brand attributes—whether communicating premium quality through metallics, wellness through natural tones, or potency through bold contrasts

-

Custom Matching Systems – Proprietary color matching ensures perfect alignment with existing brand assets across all packaging touchpoints using Pantone, RAL, and custom formulations

-

Finish Variations – Multiple finish options including matte, gloss, and metallic create distinctive visual experiences that enhance perceived value

-

Contrast Engineering – Scientifically-designed color combinations maximize shelf visibility and consumer recall in competitive retail environments

Navigating complex regulatory requirements is essential in the cannabis industry, where packaging non-compliance can result in costly product recalls, legal penalties, and brand damage. Our comprehensive approach to compliance ensures your products meet all regulatory standards while maintaining distinctive brand appeal and consumer convenience.

-

Child-Resistant Certification – Gettopac products meet ASTM D3475 and Poison Prevention Packaging Act (PPPA) requirements, with certified mechanisms that achieve child-resistance while maintaining adult accessibility

-

Tamper-Evidence Solutions – Integrated seals, bands, and breakaway components provide clear visual indication of package integrity, protecting consumers and brands from potential contamination or tampering

-

Opacity Compliance – Our range includes fully opaque and selectively opaque options that meet varying state requirements for reducing product visibility while maintaining brand presentation

-

Regulatory Labeling – We facilitate compliance with state-specific labeling requirements including universal THC symbols, cannabinoid content, mandatory warnings, and consumer information through templates and guidance

-

Material Safety – All packaging components meet food-grade requirements and are tested for leaching and migration to ensure product purity and consumer safety

Customize Your Marijuana Packaging Step by Step

Tailor Customer Segments for Diverse Industry Needs

Cannabis Library

Light up your curiosity—dive into our cannabis blogs for fresh takes, high vibes, and blunt truths.

Newsletter

Stay in the loop with global cannabis news and catch exclusive packaging deals straight from Ghettopac!