Cannabis edibles have experienced unprecedented growth across legal markets, transforming from homemade brownies into sophisticated gummies, chocolates, beverages, and artisanal confections. This surge is driven by consumer preference for smoke-free consumption and the appeal of precise dosing. However, behind every successful edible product lies a critical yet often overlooked component: packaging. Far from being merely decorative, packaging for cannabis edibles serves five essential functions that can make or break a product’s success in the marketplace.

The packaging must first and foremost ensure safety through child-resistance mechanisms and tamper-evident features that protect both intended consumers and vulnerable populations. Simultaneously, it must meet stringent compliance requirements that vary significantly across jurisdictions, including opaque materials, universal cannabis symbols, and precise dose labeling. Beyond regulatory demands, effective packaging preserves freshness and potency by creating barriers against moisture, oxygen, and light that can degrade both flavor and cannabinoid content. The packaging also serves as the primary vehicle for brand identity, communicating quality, values, and product positioning through materials, graphics, and form factors. Finally, it must enable consumer convenience through features like resealability for multi-dose products and clear single-dose identification.

The complexity of these requirements becomes apparent when examining different edible categories, each presenting unique challenges that demand specialized packaging solutions. Gummies require moisture barriers to prevent stickiness, while chocolates need temperature-controlled environments to avoid bloom. Beverages must protect emulsified cannabinoids from light degradation, and baked goods require both freshness preservation and structural protection. This comprehensive exploration examines major edible categories and details the optimal packaging solutions for each, grounded in current regulations and food science principles.

Universal Packaging Principles

Every cannabis edible package must begin with child-resistance, a requirement mandated by the Consumer Product Safety Commission under the Poison Prevention Packaging Act. This regulation stipulates that packaging must prevent access by 85% of children under age five during a standardized five-minute test, while remaining accessible to adults. Common child-resistant formats include push-and-turn jars, blister packs requiring significant force to pierce, and specialized zip-seal pouches with complex opening mechanisms. The testing protocols are rigorous, often requiring multiple iterations before achieving certification, making early consultation with packaging engineers essential for product development timelines.

The opaque versus windowed packaging debate reflects broader regulatory trends prioritizing child safety over product visibility. Most U.S. states now require fully opaque primary packaging for edibles to minimize appeal to minors, eliminating the traditional retail advantage of product visibility. Canadian regulations take this further, mandating not only opacity but restricting packaging to a single matte color, effectively creating a plain packaging environment similar to tobacco products. These requirements force brands to rely heavily on typography, texture, and shape rather than color and imagery for differentiation.

Tamper-evidence serves as both a safety measure and a quality assurance indicator, typically implemented through shrink bands, perforated pouches, or tear-tabs that clearly show if packaging has been opened. This feature becomes particularly important for edibles sold through multiple distribution channels where product integrity must be maintained from manufacturer to consumer. The visual cues provided by tamper-evident features also help budtenders and consumers identify potentially compromised products before purchase or consumption.

Barrier properties represent the technical heart of edible packaging, requiring careful material selection based on specific product vulnerabilities. Moisture barriers, typically achieved through high-barrier Mylar or foil laminates, prevent the texture changes that can render gummies inedible or create food safety risks in baked goods. Oxygen barriers slow the rancidity that can develop in fat-rich confections like chocolates, while light barriers through opaque materials or UV-blocking amber glass preserve cannabinoid stability over extended shelf life. The effectiveness of these barriers directly impacts both product quality and the economic viability of longer distribution chains.

Resealability becomes crucial for multi-dose products, where consumers may access the package multiple times over days or weeks. Zipper closures, twist caps, and snap-fit lids must maintain their barrier properties through repeated use while continuing to meet child-resistance requirements. This presents engineering challenges that often require trade-offs between convenience and safety, with some manufacturers opting for individually wrapped pieces within child-resistant master packages to optimize both factors.

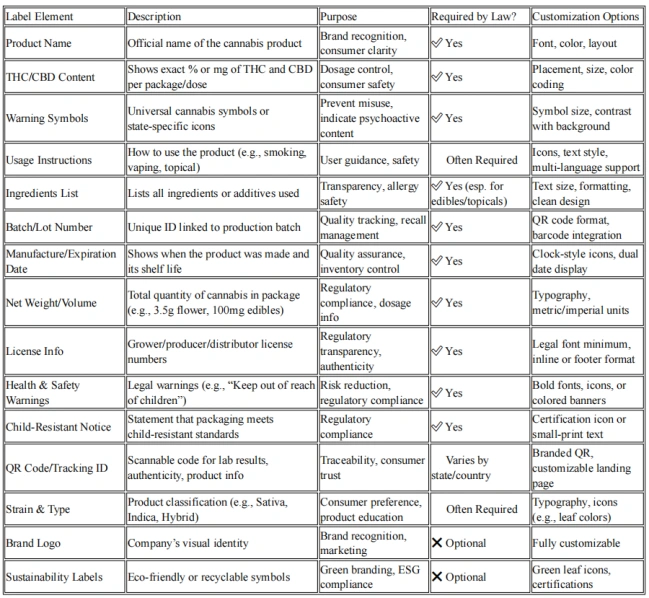

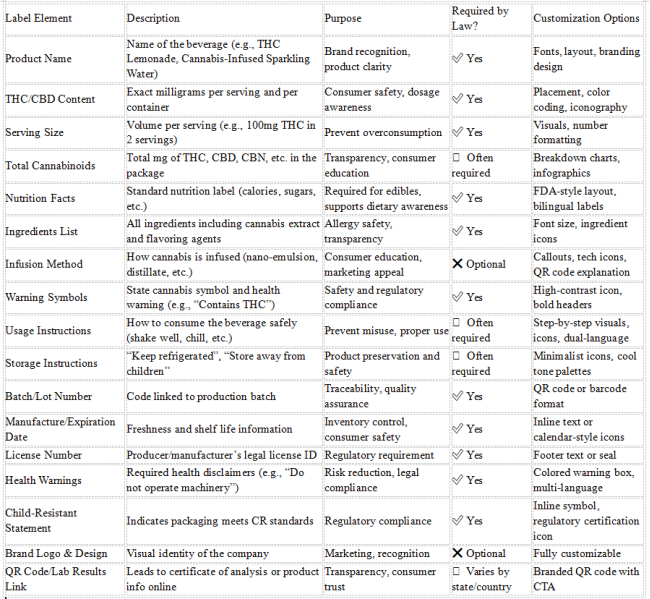

Label requirements vary significantly across jurisdictions but universally include THC content per serving and per package, universal cannabis symbols, and specific warnings. Nutrition panels may be required depending on local food labeling laws, while allergen warnings follow standard food industry protocols. Storage instructions become particularly important for temperature-sensitive products, with clear iconography indicating refrigeration needs or temperature limits. State-specific warnings, such as Washington’s “May be habit forming” requirement, add another layer of complexity to compliance management.

Sustainability considerations increasingly influence packaging decisions as environmentally conscious consumers drive demand for biodegradable films, recyclable mono-materials, and reusable glass containers. However, these eco-friendly options must still meet all safety and compliance requirements, often creating technical challenges that increase costs. The emerging availability of certified compostable films and mono-material pouches designed for store drop-off recycling programs provides manufacturers with viable options that balance environmental responsibility with regulatory compliance.

Gummies and Chews: Managing Moisture and Dosing

Gummies represent the largest segment of the edibles market, yet their seemingly simple appearance masks complex packaging challenges rooted in sugar chemistry and moisture dynamics. The primary enemy of gummy quality is moisture migration, which can transform perfectly textured products into sticky masses or brittle fragments depending on the direction of water movement. When gummies lose moisture to low-humidity environments, they become hard and potentially cracked, while excess moisture absorption in humid conditions creates surface stickiness and potential microbial growth. Sugar bloom, the crystallization of sugars on the gummy surface, creates visual defects that consumers associate with poor quality or age, even when the product remains safe for consumption.

The packaging solution for gummies centers on child-resistant Mylar pouches utilizing three-to-five-mil food-grade foil laminates. These multi-layer constructions typically combine polyester for strength, aluminum foil for barrier properties, and polyethylene for heat sealability. The high-barrier characteristics block both moisture and oxygen transmission, creating a stable microenvironment that preserves texture and prevents oxidation of any fat-soluble compounds. Zip-lock closures provide resealability essential for multi-dose packages while maintaining the integrity of the moisture barrier through repeated openings. Perforated tear notches with tamper-evident seals ensure that consumers can immediately identify whether packages have been previously opened.

For premium positioning or larger package sizes, rigid PET or glass jars offer superior protection and enhanced brand perception. Amber-colored PET blocks light that can degrade cannabinoids, while glass provides the ultimate barrier against flavor transfer and chemical migration. Push-turn or screw caps with child-resistant mechanisms must be carefully selected to ensure proper sealing force without compromising accessibility for arthritis sufferers or elderly consumers. Shrink bands provide clear tamper evidence while adding an additional moisture barrier around the closure interface.

Individual wrapping of gummy pieces within the master package addresses both hygiene concerns and dosing accuracy. Heat-sealed films around each piece prevent moisture exchange between gummies that might otherwise stick together, while clearly delineating individual doses for consumers. This approach supports accurate dosing protocols and reduces contamination risks during handling, particularly important for medical patients with compromised immune systems.

Design considerations for gummy packaging must carefully navigate child appeal restrictions while maintaining brand recognition. Cartoon imagery, fruit characters, and bright rainbow palettes that could attract children are prohibited in most jurisdictions, forcing brands toward more sophisticated design approaches. Matte finishes and limited color palettes not only comply with plain packaging trends but can enhance perceived product quality when executed thoughtfully. The prominent display of per-piece THC content and total package dosage becomes a design element in itself, often integrated into the overall visual hierarchy rather than treated as mandatory fine print.

Chocolates and Baked Goods: Temperature and Aroma Control

Chocolate-based edibles present unique packaging challenges rooted in cocoa butter’s polymorphic behavior and chocolate’s sensitivity to environmental conditions. Heat sensitivity means that chocolates can melt and develop bloom if temperature isn’t carefully controlled throughout the supply chain, while the porous nature of chocolate makes it susceptible to absorbing odors from packaging materials or the surrounding environment. Fat bloom, manifesting as a white film on chocolate surfaces, results from cocoa butter migration and temperature fluctuations, creating visual defects that suggest staleness even when the product remains safe and potent.

The optimal packaging approach for chocolates employs a dual-layer strategy beginning with individual piece protection. Foil or compostable flow-wrap around individual truffles or chocolate squares provides the first line of defense against light, oxygen, moisture, and odor migration. Metalized films offer superior barrier properties, while emerging compostable options from materials like PLA provide environmental benefits without compromising protection. The intimate contact between wrapper and chocolate surface prevents air circulation that could accelerate bloom formation while maintaining the chocolate’s distinct flavor profile.

Child-resistant paperboard boxes or tins serve as the secondary package, housing individually wrapped chocolates while providing structural protection and brand presentation opportunities. Rigid construction prevents crushing during transport and handling, while tamper-evident stickers or shrink sleeves clearly indicate package integrity. Resealable tuck-flaps or hinge-lids with child-resistant latches balance accessibility with safety requirements, though some jurisdictions may require additional child-resistant mechanisms depending on total THC content.

Baked goods like brownies and cookies require different packaging approaches due to their higher moisture content and different textural concerns. Insulated gusseted pouches with high-barrier laminated construction and internal foil lining create a stable environment that prevents moisture loss leading to staleness. Desiccant packets carefully sized to absorb excess moisture without over-drying the product help maintain optimal texture throughout shelf life. Zipper seals and tear notches provide resealability and tamper evidence while accommodating the irregular shapes common in artisanal baked goods.

Design considerations for chocolate and bakery product packaging must address allergen labeling requirements that are often more complex than for other edible categories. Dual-language allergen panels clearly identifying wheat, eggs, dairy, nuts, and other common allergens follow established food industry protocols while meeting cannabis-specific requirements. Clear storage iconography indicating temperature limits, such as “Store below 24°C,” helps consumers maintain product quality in varying climate conditions. Partitioned blister trays for brownies prevent pieces from sticking together while providing portion control that supports accurate dosing.

The visual presentation of chocolate packaging must carefully avoid resembling non-cannabis confectionery brands while maintaining the premium associations consumers expect from quality chocolate products. This requires sophisticated design approaches that leverage texture, typography, and subtle color variations rather than the bright imagery traditionally associated with candy marketing.

Cannabis Beverages and Syrups: Protecting Emulsions and Carbonation

Cannabis beverages represent one of the fastest-growing segments of the edibles market, driven by consumer familiarity with beverage consumption and the rapid onset enabled by nano-emulsion technology. However, these products present complex packaging challenges related to light degradation of emulsified cannabinoids, carbonation retention in THC-infused sodas, and leak prevention during distribution. The emulsification process that enables cannabinoids to dissolve in water-based beverages creates unstable systems that can separate or degrade when exposed to light, temperature fluctuations, or mechanical stress.

Opaque, shrink-sleeved aluminum cans provide the optimal solution for carbonated cannabis beverages, offering complete light protection while maintaining the structural integrity necessary for pressurized products. Twelve-ounce cans with full-body shrink sleeves allow for comprehensive brand graphics while meeting opacity requirements across all jurisdictions. Nitrogen-dosed headspace during filling displaces oxygen that could interact with both cannabinoids and carbonation systems, extending shelf life and maintaining product quality. Pop-top child-resistant tabs or resealable screw-caps accommodate both single-serving and multi-serving consumption patterns while maintaining carbonation between uses.

Amber glass bottles serve premium positioning for syrups and non-carbonated beverages, with UV-blocking properties that protect light-sensitive compounds. Bottle sizes ranging from 200mL to 500mL accommodate different dosing strategies, from single-serving shots to multi-use concentrates. Child-resistant crown caps or tamper-band caps provide security and compliance, while integrated dosing cups in cap liners help consumers measure accurate portions. Secondary cardboard carriers may be required in jurisdictions mandating opaque outer packaging, creating additional brand presentation opportunities while ensuring regulatory compliance.

High-barrier PET bottles offer a cost-effective alternative for non-carbonated drinks, utilizing EVOH barrier layers to prevent flavor loss and extend shelf life. Pressure-tight child-resistant caps maintain product integrity while providing the security features required for cannabis products. The lighter weight and shatter-resistance of PET make it particularly suitable for multi-serving products likely to be transported by consumers.

Beverage packaging design must clearly communicate dosing information that can be more complex than solid edibles due to varying serving sizes and concentration levels. Per-serving THC content expressed as milligrams per ounce provides consumers with flexible dosing options, while total THC per container ensures compliance with package limits. Onset timing indicators become particularly important for beverages, with nano-emulsion products requiring clear identification of their 15-minute onset compared to 45-60 minutes for traditional emulsions. “Shake well” instructions and refrigeration requirements add additional complexity to label design that must be accommodated within limited space constraints.

The beverage category’s familiarity to consumers creates both opportunities and risks in packaging design. While consumers readily understand beverage formats, the risk of confusion with non-cannabis products requires careful differentiation through cannabis symbols, warning statements, and design elements that clearly identify products as containing THC while avoiding appeal to minors.

Hard Candies and Lozenges: Unit Dose Precision

Hard candies and lozenges offer unique advantages in precise dosing and discrete consumption, but their packaging must address the specific challenges of preventing moisture absorption that can cause stickiness, protecting against breakage, and clearly delineating individual doses. The brittle nature of hard candies makes them susceptible to cracking and breaking, while their hygroscopic properties mean they readily absorb moisture from humid environments, leading to texture changes and potential microbial growth.

Blister packs represent the optimal packaging solution for hard candies, utilizing thermoformed PET or PVC cavities with aluminum foil backing to create individual protective chambers for each piece. The push-through mechanism required to access each candy provides inherent child-resistance while clearly delineating unit doses. Perforated aluminum foil backing offers tamper evidence, as any attempt to access the product creates visible damage to the packaging. The excellent moisture barrier properties of foil laminates prevent the humidity-related texture changes that can render hard candies unpalatable.

Metal tins with food-grade lacquer linings provide an alternative packaging approach that appeals to consumers seeking premium presentation and reusability. Slim, hinged, or slip-lid tins create a protective environment for multiple pieces while offering opportunities for sophisticated branding. Interior paper inserts or foam pads prevent rattling during transport while protecting candies from damage. Child-resistant closures through friction-fit or snap-lock mechanisms must be carefully engineered to ensure compliance with CPSC protocols while maintaining the aesthetic appeal that drives premium positioning.

The individual nature of hard candy consumption makes dose control particularly straightforward compared to other edible formats, but this advantage requires careful attention to shape and appearance restrictions. Fruit-shaped candies or cartoon configurations that might appeal to children are prohibited in most jurisdictions, requiring manufacturers to develop distinctive shapes that avoid these restrictions while maintaining visual appeal. State and provincial THC limits per item and per package must be carefully considered during product development, as the concentrated nature of hard candies can quickly approach regulatory limits.

Compliance considerations for hard candy packaging must address the specific risks associated with products that closely resemble traditional confectionery. Universal THC symbols must be prominently displayed on both individual pieces where possible and primary packaging. Mandatory warnings such as “Keep out of reach of children” require careful integration into design schemes that may have limited space for text elements. The challenge lies in creating packaging that clearly identifies cannabis content while maintaining the sophisticated presentation expected by adult consumers.

Savory Snacks: Preventing Rancidity and Maintaining Texture

The emerging category of cannabis-infused savory snacks, including chips, popcorn, and nuts, presents unique packaging challenges centered on preventing oil oxidation that leads to rancidity while maintaining the crispy textures that define product quality. Unlike sweet edibles where sugar provides some preservation benefits, savory snacks rely heavily on fats and oils that are susceptible to oxidation, particularly when exposed to light, air, and temperature fluctuations. The challenge is compounded by consumer expectations for extended shelf life and the irregular shapes of many snack products that can create packaging inefficiencies.

High-barrier nitrogen-flushed stand-up pouches provide the optimal solution for most savory snack applications, utilizing multi-layer laminates that typically combine PET for strength, aluminum for barrier properties, and LLDPE for sealability. The nitrogen flush process displaces oxygen at the point of filling, creating an inert atmosphere that prevents oxidation reactions. Matte or opaque exterior finishes meet child-resistance appeal requirements while providing superior printability for brand graphics and compliance information. Zipper closures sealed post-fill maintain the modified atmosphere while providing consumer convenience for multi-serving packages.

The resealability aspect becomes particularly important for savory snacks, as consumers often consume these products over multiple occasions. Tear notches provide initial access while preserving the zipper closure for subsequent use. The challenge lies in maintaining barrier properties through repeated opening and closing cycles, requiring careful selection of zipper mechanisms that maintain their seal integrity over time.

For larger snack packages or premium positioning, resealable rigid containers offer enhanced protection and brand presentation opportunities. Round or square food-grade plastic tubs with child-resistant snap lids accommodate bulk products while providing the structural protection necessary for delicate items like flavored popcorn. The larger surface area available on rigid containers enables more comprehensive nutrition and dosing information while providing space for QR codes linking to additional product information.

Design considerations for savory snack packaging must address the unique challenge of communicating THC content in products where serving sizes may be less clearly defined than individual candies or measured beverages. Per-serving THC content expressed in milligrams alongside recommended serving sizes in grams helps consumers understand appropriate dosing. “Consume within X days after opening” guidance becomes particularly important for oil-containing products where quality degradation may occur more rapidly once the package is opened.

The integration of smart packaging technologies shows particular promise in the savory snack category, where QR codes can link to freshness trackers, detailed lab results, and interactive dosing calculators that account for individual tolerance levels and consumption goals. These digital enhancements provide value-added services that justify premium pricing while supporting responsible consumption practices.

Powders and Drink-Mix Sticks: Moisture Protection and Portion Control

Cannabis-infused powders, including hot chocolate blends, matcha mixes, and powdered gummy formulations, require packaging solutions that prioritize moisture protection above all other considerations. Moisture is the primary enemy of powdered products, causing clumping, caking, and potential microbial growth that can render products unusable or unsafe. The challenge is compounded by the need for precise portion control, as powdered products can be difficult to measure accurately without proper packaging design.

Single-dose stick packs represent the optimal packaging solution for most powdered applications, utilizing foil laminate constructions that typically combine PET for strength, aluminum foil for moisture barrier, and PE for heat sealability. The individual portion control provided by stick packs eliminates dosing uncertainty while ensuring product freshness for each use. Peel-away tear tabs require sufficient dexterity to meet child-resistance requirements while remaining accessible to adult consumers.

Master box packaging for multi-stick products must address child-resistance requirements that vary depending on total THC content and local regulations. Child-resistant rigid board cartons house individual stick packs while providing brand presentation opportunities and space for comprehensive product information. Some jurisdictions require each individual stick to meet child-resistance standards, while others allow the master package to provide primary protection.

The powder format enables unique dosing strategies not available with other edible categories, as consumers can easily adjust serving sizes by using partial stick contents or combining multiple sticks. This flexibility requires clear mixing instructions that specify liquid ratios, temperature requirements, and mixing techniques for optimal product performance. “Empty 1 stick into 8 oz water” type instructions must be prominent and unambiguous to ensure consistent consumer experience.

Quality considerations for powdered products extend beyond basic moisture protection to include issues like caking prevention and flow properties that affect consumer experience. Anti-caking agents and flow aids used in food powder manufacturing must be compatible with cannabis extracts and comply with local regulations regarding approved ingredients. The packaging must maintain these additive effects throughout shelf life while preventing moisture ingress that could compromise flow properties.

Design challenges for powder packaging include accommodating variable product densities and fill volumes while maintaining consistent package appearance. Stick pack dimensions must be optimized for the specific product formulation, balancing ease of handling with cost considerations. Clear windows in master packaging may be prohibited in some jurisdictions, requiring alternative methods to communicate product color and texture to consumers.

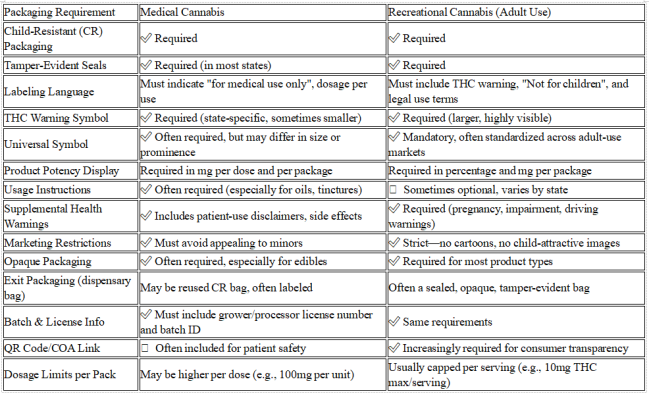

Regulatory Landscape: Medical versus Recreational Requirements

The regulatory environment governing cannabis edible packaging varies significantly between medical and recreational markets, with medical programs often allowing more flexibility in packaging design while maintaining strict safety requirements. Medical markets typically permit smaller dosage units, recognizing that patients may require micro-dosing strategies not common in recreational use. The allowance for transparent windows in some medical programs reflects the greater emphasis on patient reassurance and product verification over child-appeal concerns.

Recreational markets impose stricter aesthetic controls designed to minimize normalization and appeal to minors. Fully opaque packaging requirements eliminate traditional retail advantages of product visibility, forcing brands to rely on other differentiation strategies. Plain packaging initiatives in jurisdictions like Canada and certain U.S. states effectively create tobacco-style marketing restrictions that prioritize public health concerns over commercial interests.

The evolution of packaging requirements reflects broader regulatory trends toward treating cannabis products more like tobacco than traditional food products. Single matte color requirements in Canada represent the most restrictive approach currently implemented, while other jurisdictions continue to allow more design flexibility within opacity and child-appeal restrictions. Universal symbol requirements vary significantly between jurisdictions, with some requiring specific colors, sizes, and placement while others provide more flexibility in implementation.

Potency limits per package and per serving create additional packaging design challenges, particularly for products where traditional serving sizes might exceed regulatory limits. The 100mg total THC limit common in many U.S. states requires careful portion control for high-potency products, while Canada’s 10mg per edible item limit affects product development strategies across all categories. These regulatory constraints directly influence packaging decisions, as smaller serving sizes may require different packaging approaches than larger portions.

Labeling requirements continue to evolve as regulators gain experience with legal markets and respond to public health concerns. Mandatory warning statements have expanded beyond basic “keep out of reach of children” messages to include onset timing, duration of effects, and specific health warnings. The integration of these expanding requirements into package designs that remain commercially viable represents an ongoing challenge for manufacturers and packaging designers.

Sustainability and Future Innovations

Environmental considerations increasingly influence cannabis packaging decisions as brands respond to consumer demand for sustainable practices and regulatory pressure to reduce environmental impact. The challenge lies in developing eco-friendly solutions that maintain the safety, compliance, and quality protection requirements essential for cannabis products. Traditional sustainable packaging materials often lack the barrier properties or child-resistance capabilities necessary for cannabis applications, requiring innovative approaches to balance environmental responsibility with regulatory compliance.

Mono-material pouches designed for recyclability through store drop-off programs represent one promising approach, utilizing single polymer constructions that can be processed through existing recycling infrastructure. These pouches require careful design to achieve adequate barrier properties without multi-layer laminations that complicate recycling. The trade-off often involves accepting shorter shelf life in exchange for environmental benefits, requiring supply chain adjustments to maintain product quality.

Compostable films from materials like PLA (polylactic acid) or TIPA offer biodegradability benefits but require validation for food safety applications and performance testing under various environmental conditions. The regulatory approval process for new packaging materials can be lengthy, requiring early planning for brands interested in sustainable packaging options. Performance characteristics like moisture barrier, heat resistance, and printability may differ from traditional materials, requiring formulation adjustments or design modifications.

Glass return programs for premium products provide sustainability benefits while enhancing brand loyalty through deposit-return systems. These programs require logistical infrastructure to collect, clean, and redistribute containers while maintaining compliance with cannabis tracking requirements. The higher initial cost of glass packaging can be offset by reduced material costs in return programs while supporting premium positioning strategies.

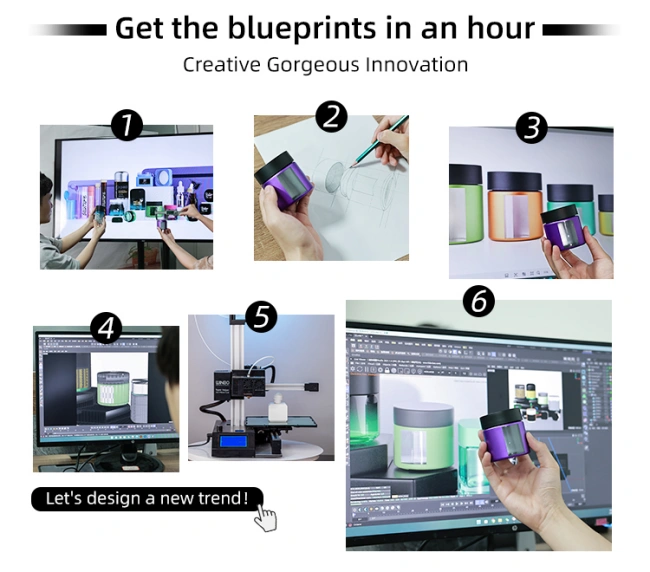

Smart packaging technologies represent the next frontier in cannabis edible packaging, with NFC tags enabling real-time access to lab results, freshness sensors providing objective quality indicators, and QR codes linking to interactive dosing calculators and consumption tracking tools. These technologies add functionality that can justify premium pricing while supporting responsible consumption practices through education and monitoring capabilities.

Active packaging concepts from the broader food industry show promise for cannabis applications, including edible biopolymer coatings infused with antioxidants that could extend shelf life while eliminating secondary packaging requirements. Research into antimicrobial packaging surfaces and oxygen-scavenging materials could address specific challenges in cannabis product preservation while reducing packaging material requirements.

Implementation Guidelines and Best Practices

Successful cannabis edible packaging requires careful coordination between product development, regulatory compliance, and packaging engineering from the earliest stages of product conception. The complexity of requirements across multiple jurisdictions demands systematic approaches to packaging selection that consider all relevant factors before committing to specific solutions. A structured evaluation process can prevent costly mistakes and ensure optimal outcomes for both regulatory compliance and commercial success.

The barrier fit assessment should begin with detailed analysis of the specific product’s vulnerabilities to moisture, oxygen, light, and temperature. Products containing fats require oxygen barrier protection to prevent rancidity, while gummy products need moisture control to maintain texture. Light-sensitive products require opaque materials or UV-blocking additives, while temperature-sensitive items may need insulation or specific storage instructions. The shelf life requirements and distribution environment directly influence barrier property specifications.

Child-resistance certification requires early engagement with certified testing laboratories to validate packaging designs under CPSC or ASTM protocols. The testing process can take several weeks and may require design modifications, making early validation essential for product launch timelines. Alternative packaging designs should be developed concurrently to avoid delays if initial concepts fail certification testing.

Print space allocation and compliance label requirements must be carefully planned to accommodate all mandatory elements while maintaining commercial appeal. The universal cannabis symbol, THC content, warnings, nutrition facts, and storage instructions compete for limited space on smaller packages. Hierarchical information design helps prioritize critical safety information while integrating compliance elements into overall brand presentation.

Vendor selection and supply chain management present unique challenges in cannabis packaging due to specialized requirements and limited supplier base. Lead times for custom packaging designs can extend beyond standard food packaging timelines, while minimum order quantities may exceed initial production requirements for new products. Vendor qualification should include validation of cannabis industry experience and understanding of regulatory requirements.

Sustainability claims and certifications require verification through third-party organizations to avoid greenwashing accusations and regulatory violations. Compostable certifications, recyclability claims, and sustainable sourcing statements must be supported by appropriate documentation and testing. The cost implications of sustainable packaging options should be evaluated against brand positioning and consumer willingness to pay premium prices for environmental benefits.

The future of cannabis edible packaging lies in the successful integration of safety, compliance, sustainability, and consumer convenience into solutions that support both responsible consumption and commercial success. As regulatory frameworks mature and consumer expectations evolve, packaging innovations will continue to play a crucial role in shaping the cannabis edibles market. Brands that invest in thoughtful packaging strategies today will be best positioned to adapt to changing requirements while building lasting consumer relationships based on trust, quality, and responsibility.