Got Questions?

Throw them at Ghettopac—we’re all ears and ready to roll!

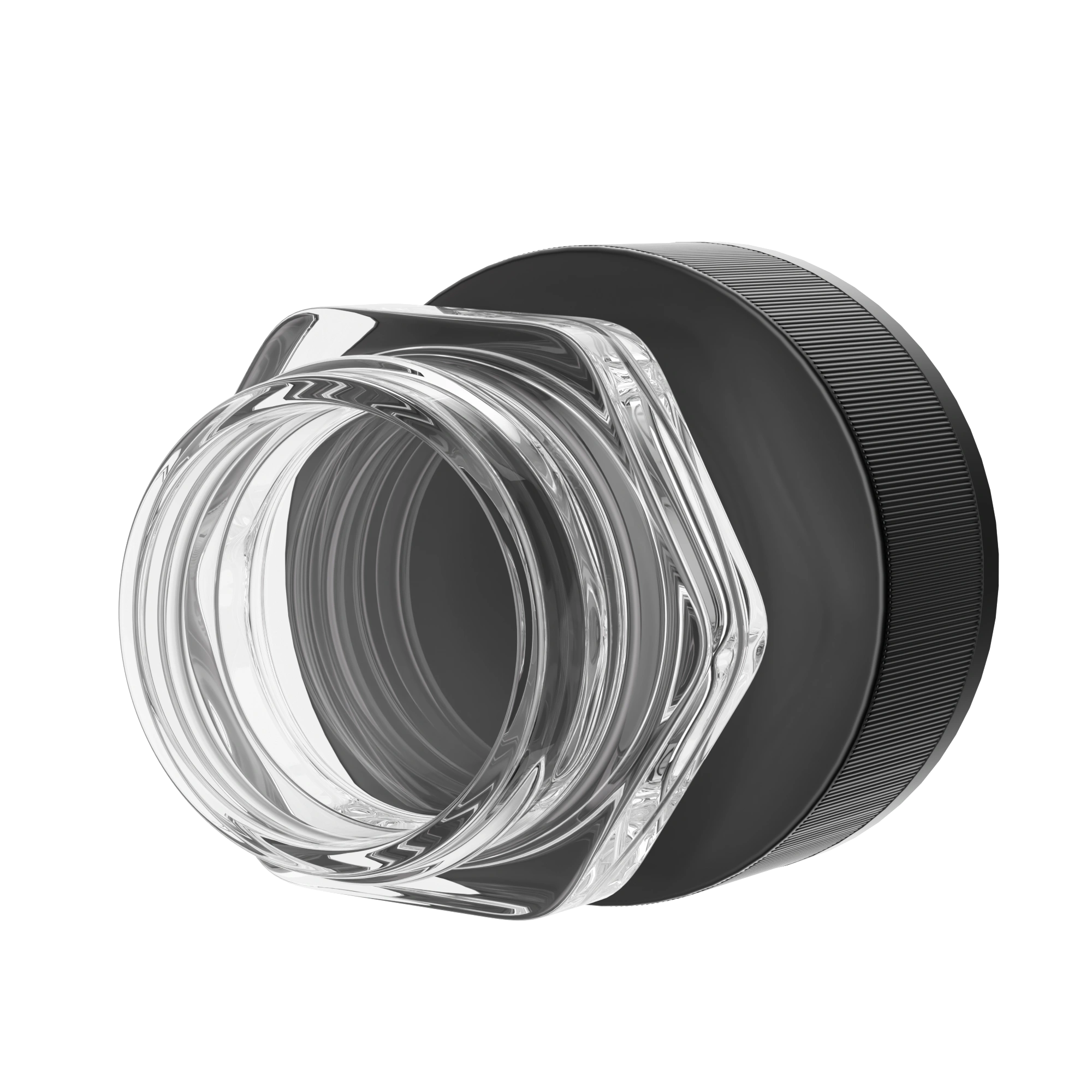

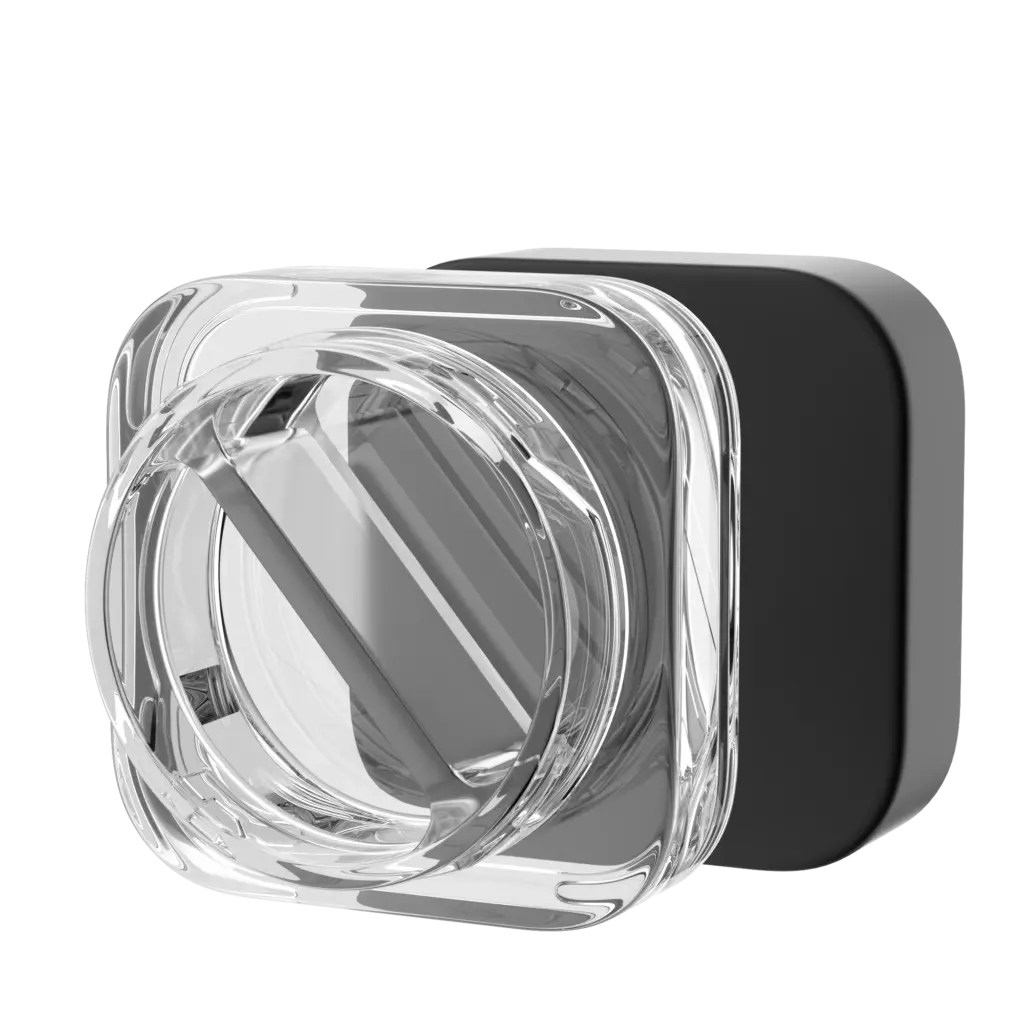

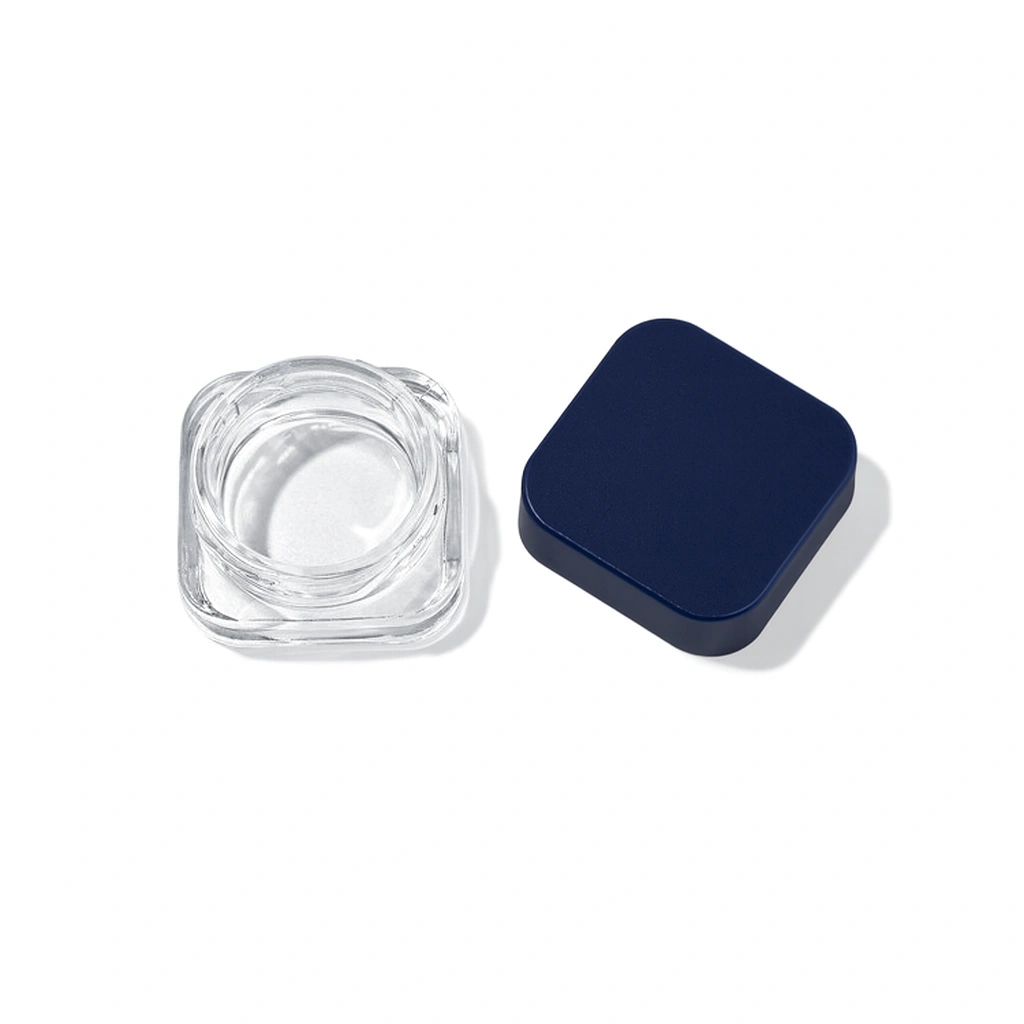

Cannabis concentrate jars are specialized glass containers designed exclusively for storing high-potency cannabis extracts including wax, shatter, crumble, budder, live resin, and rosin. These precision-engineered vessels serve as the critical barrier between your valuable concentrates and environmental factors that can degrade quality, potency, and flavor profiles.

Preserve concentrate integrity and prevent contamination

Maintain optimal potency and terpene profiles over extended periods

Provide regulatory-compliant packaging for licensed cannabis businesses

Enable professional product presentation in retail environments

Licensed dispensaries requiring compliant retail packaging

Cannabis processors and manufacturers for product storage and distribution

Testing laboratories for sample preservation and transport

Medical cannabis facilities serving registered patients

Glass concentrate containers represent the pinnacle of cannabis storage technology, offering unmatched preservation capabilities that directly impact product quality and consumer satisfaction.

Glass is completely chemically inert, meaning it will never interact with cannabis compounds or leach foreign substances into your concentrates. Unlike plastic alternatives that can absorb terpenes or introduce unwanted flavors, glass maintains the authentic taste, aroma, and effects your customers expect.

The molecular structure of glass creates an impermeable barrier against moisture, oxygen, and volatile compounds. This protection is crucial for maintaining concentrate consistency – preventing wax from becoming too dry or sauce from separating over time.

Clear glass provides complete product visibility, allowing customers to assess quality, color, and texture before purchase. This transparency builds trust and confidence in your brand while showcasing the craftsmanship of your extraction process.

Glass is 100% recyclable without quality loss, supporting sustainable business practices and appealing to environmentally conscious consumers. Unlike single-use plastic containers, glass jars can be repurposed by customers, extending their lifecycle and reducing waste.

Ultraviolet-blocking amber or violet glass harnesses embedded minerals to filter damaging UVA/UVB rays, curbing cannabinoid oxidation and terpene loss; this smart barrier extends shelf life and safeguards potency across retail displays.

UV radiation rapidly breaks down THC, CBD, and other cannabinoids, converting them into less potent compounds. Amber or UV-blocking glass containers filter harmful wavelengths that cause this molecular degradation, preserving concentrate strength and therapeutic effectiveness over extended periods.

Volatile terpenes responsible for concentrate flavor and aroma are particularly sensitive to light exposure. UV-protective containers maintain these delicate aromatic compounds that contribute to the entourage effect, ensuring concentrates retain their distinctive sensory characteristics and therapeutic synergies.

UV protection significantly extends concentrate storage life by preventing photodegradation reactions that alter product chemistry. This protection maintains consistent potency, flavor, and appearance for months longer than clear containers, providing better value and consumer satisfaction.

Amber-tinted glass combines UV protection with the inert properties of glass storage, offering optimal preservation without additional coatings. This natural filtration blocks 99% of harmful UV rays while maintaining product visibility for quality assessment and professional presentation.

Elegant glazed ceramic jars merge artisan aesthetics with lab-grade performance, offering an inert, heat-resistant, naturally opaque shelter that locks out light, flavors, and contaminants—ideal for premium concentrates demanding long-term freshness and terpene fidelity.

Ceramic containers offer completely inert surfaces that never react with cannabis compounds, ensuring zero flavor contamination or chemical leaching. This non-reactive nature preserves the authentic taste, aroma, and therapeutic properties of concentrates better than many alternatives.

Premium ceramic materials withstand extreme temperatures without degradation, making them ideal for concentrates stored in varying climates. This thermal stability prevents container breakdown that could compromise product integrity or introduce harmful particles into stored concentrates.

Ceramic’s inherent opacity provides excellent protection against light exposure, which can degrade cannabinoids and terpenes over time. This natural UV barrier eliminates the need for additional protective measures while maintaining concentrate potency during extended storage periods.

While ceramic offers excellent preservation properties, it requires careful handling due to potential breakage upon impact. Quality zirconia ceramics provide enhanced crack resistance, but all ceramic containers need protective packaging and gentle handling to prevent product loss from breakage.

A child-resistant plastic cap offers essential protection for cannabis concentrates by employing locking mechanisms only adults can easily open. These caps help prevent accidental ingestion by children, ensure regulatory compliance, and provide peace of mind for consumers and retailers alike.

Child-resistant plastic caps employ locking mechanisms, push-and-turn, that require coordinated actions beyond the ability of most children, greatly reducing the risk of accidental access to cannabis concentrates.

These caps are usually made from durable PP or ABS, offering lightweight strength, chemical resistance, and secure sealing to protect contents from moisture and contamination while surviving regular handling and transport.

They are available in a variety of finishes—matte, ribbed, or smooth—for both function and branding. Brands can choose custom colors, logo printing, or labeling to maintain design consistency without sacrificing safety or compliance.

A Teflon gasket is a premium sealing solution placed inside the jar lid, designed to deliver an airtight, chemical-resistant barrier. This layer prevents leaks and contamination, ensuring that sensitive cannabis concentrates stay fresh, potent, and protected throughout storage and transport.

A Teflon (PTFE) gasket forms an exceptionally tight seal between the jar and the cap, preventing leaks and preserving freshness. Its non-stick nature ensures easy jar opening and product removal even after long storage.

Resistant to nearly all chemicals and temperatures, Teflon gaskets maintain their integrity regardless of concentrate ingredients, eliminating contamination risk and providing long-term reliability for both medical and adult-use markets.

Concentrate jars are offered in three practical capacity classes—compact 3 / 5 g, mid-size 7 / 9 g, and fully custom—so brands can match package volume to product strategy and consumer habits.

Beyond material and closure choices, modern concentrate jars can feature compartments that organize multiple extracts under one lid. Whether a minimalist single bay or multi-chamber sampler, these internal dividers help brands reduce SKUs, save shelf space, and delight variety-seeking consumers.

A one-chamber design keeps the entire interior dedicated to a single extract, so terpenes from different strains never mingle. Its simplicity speeds up filling lines, lowers material cost per unit, and gives end-users a familiar, no-guesswork experience—open, dab, reseal.

An internal divider splits the vessel into two equal bays, letting brands pair complementary textures—e.g., live resin and crumble—or offer day-versus-night strains in one SKU. Consumers can sample variety while carrying only one child-resistant lid, saving pocket space and reducing plastic waste.

Three wedge-shaped wells transform a 5- to 7-mL jar into a mini “flight,” ideal for seasonal sampler packs or tiered potency options. Retail staff can showcase multiple grams under a single barcode, streamlining inventory, while buyers enjoy budget-friendly tasting sets that stay neatly separated until use.

Beyond functional sealing, jar surfaces double as billboards. Coatings, print treatments, and textural effects turn plain glass and cap into a premium touchpoint, attracting eyes in the display case, protecting terpenes from light, and reinforcing sustainability or luxury cues consumers value today.

Opaque lacquer layers tint clear glass any Pantone shade, amplifying brand identity, blocking degrading light, and masking extract residue while keeping internal terpene profile untouched.

Acid-etched or sandblasted frosting diffuses incoming light, reduces finger smudges, and creates a velvety matte feel consumers associate with premium, small-batch extracts for visual elegance.

Silk-screen printing suits simple designs under four colors, offering durability and precision, while digital printing enables complex, multi-color graphics, ideal for detailed, high-impact packaging finishes.

Metallic hot-foil stamping presses gold, silver, or holographic foils into the surface, spotlighting logos and strain names while emphasising luxury and catching budtender lighting angles.

Vacuum electroplating envelops glass in ultra-thin chrome, rose-gold, or rainbow metal, yielding mirror brightness, scratch resistance, and complete light block without adding bulky secondary sleeves.

Bamboo veneer wraps child-resistant lids in fast-renewing wood, delivering a warm eco-luxury aesthetic while cutting visible plastic and signaling sustainability credentials to conscious consumers.

Borosilicate or soda-lime glass is inert, airtight, and UV-resistant, preserving terpene flavour and potency far better than plastics that can leach or absorb volatile compounds.

Yes. All adult-use and medical states now mandate PPPA-compliant CR packaging for extracts; regulators test a random sample of lids with panels of ≤5-year-olds (85% must fail within five minutes) and healthy seniors (90% must succeed) before the SKU can enter commerce. Non-compliant brands risk product recalls and five-figure civil fines; CR pouches are allowed only for bulk sizes when certified jar lids are unavailable.

The primary panel must show product identity, net weight in grams, and the universal cannabis symbol. An adjacent information panel lists total and per-serving THC/CBD, full batch/lot ID, manufacture and test dates, licensed producer number, mandated health warnings, ingredients, and activation-time guidance; Washington’s WAC 314-55-105 and California CCR §17407 are common reference templates that many multi-state operators follow nationwide.

Best practice is a two-step clean: first rinse in food-grade detergent, then run 30 minutes in a 35 °C ultrasonic bath of reverse-osmosis water; jars are air-dried in an ISO-8 clean zone and capped only after internal RH <10% to prevent mould growth or water activity spikes that can nucleate sugaring in live resin.

Glass containers undergo five ASTM/ISO routines: pressure-burst (verifies ≥1.0 MPa internal resistance), axial-load (ensures stack strength), 45 °C→0 °C thermal-shock, hydrolytic-resistance titration (Type III limits on alkali leachables), and vacuum-decay or dye-ingress seal checks after capping; only lots that pass all metrics are released to the filling line.

Maintain 60–70 °F, low light, and minimal oxygen headspace; reseal immediately after each dab. Cooler temperatures slow terpene evaporation, while darkness prevents UV-driven THC-to-CBN conversion—both reactions that flatten flavour and potency in as little as four weeks if jars are left open or in direct sunlight.

Yes. A thin bamboo veneer is bonded to a certified polypropylene core that passes FDA 21 CFR §177 food-contact and ISO-8317 child-resistance tests; the wood never touches concentrate, but it replaces visible petroleum plastic, giving brands an eco-luxury aesthetic without sacrificing regulatory performance.

Ghettopac (Jarsking) stock 3/5 g and 7/9 g formats, yet will cut new moulds for any volume, emboss logos in the glass, add UV-blocking tints, or apply silk-screen graphics and chrome electroplating. Minimum orders for bespoke tooling start around 10 000 units, letting multi-state brands unify compliance while differentiating shelf presence.