Premium glass construction provides superior terpene preservation and chemical inertness for high-end concentrate products.

Cannabis Concentrates

Cannabis concentrates represent the pinnacle of potency and purity in cannabis products, offering concentrated forms of cannabinoids and terpenes extracted from premium flower. These highly potent products including live resin, rosin, shatter, wax, distillate, and diamonds require specialized packaging solutions that preserve their unique consistencies, prevent degradation, and maintain their premium quality from production to consumption.

Material Compatibility

Consistency Variations

Terpene Preservation

Non-Stick Requirements

Premium Presentation

Temperature Sensitivity

In stock

Material

Custom Plastic Tube Child Resistant Container Bottle

Custom Plastic Tube Child Resistant Container Bottle

Custom Plastic Tube Child Resistant Container Bottle

Custom Plastic Tube Child Resistant Container Bottle

Custom Plastic Tube Child Resistant Container Bottle

Custom Plastic Tube Child Resistant Container Bottle

From Laboratory to Luxury

Advanced Cannabis Concentrate Packaging Solutions

Requirement:

Cannabis concentrates exhibit diverse consistencies from liquid distillates to brittle shatter, each requiring specialized container designs that accommodate specific handling, storage, and dispensing needs while preventing product loss and contamination.

Ghettopac Solution:

Engineered for performance and compliance, our concentrate containers combine precision-molded dimensions, airtight sealing, and purpose-built dispensing for both solids and liquids. Designed to maximize product yield, protect terpene integrity, and meet all regulatory standards, they help cannabis brands deliver premium quality while standing out in a competitive market.

Requirement:

Concentrated cannabis products contain highly volatile terpene compounds that rapidly degrade when exposed to light, oxygen, or temperature fluctuations, resulting in flavor loss, potency reduction, and diminished consumer experience.

Ghettopac Solution:

Multi-barrier protection systems combining UV-filtering glass, nitrogen-flush compatible sealing, and thermal-stable materials. Our containers feature humidity control chambers and light-blocking coating that preserve terpene profiles and cannabinoid integrity throughout extended storage periods.

Requirement:

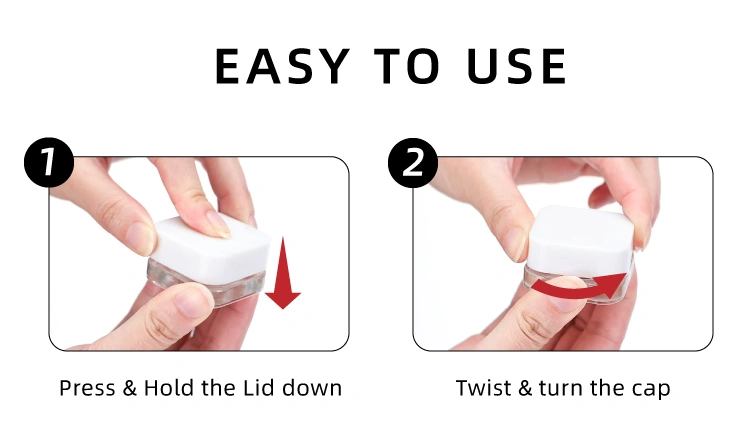

Concentrate packaging must accommodate ASTM-certified child-resistant mechanisms while maintaining convenient adult operation despite varying container shapes, sizes, and materials used across different product categories.

Ghettopac Solution:

Universal child-resistant closure systems engineered for multiple container formats including push-and-turn caps for jars, squeeze-to-release mechanisms for tubes, and press-and-slide systems for specialized containers. All designs maintain consistent adult accessibility while exceeding safety requirements across hundreds of use cycles.

Requirement:

High-potency concentrates create intense aromatic signatures requiring complete odor containment for legal compliance, consumer discretion, and product quality maintenance during storage and transport.

Ghettopac Solution:

Advanced hermetic sealing technology featuring silicone gasket systems and molecular barrier films. Our odor-proof designs prevent terpene migration while preserving aromatic intensity within containers for optimal consumer experience upon opening.

Requirement:

Premium concentrate products command high margins but require packaging that communicates quality, potency, and craftsmanship to justify pricing and differentiate from lower-tier offerings in crowded dispensary displays.

Ghettopac Solution:

Luxury finishing techniques including soft-touch coatings, holographic security features, precision embossing, and custom color-matching. Our premium materials and sophisticated design elements create memorable shelf presence while highlighting product quality indicators that influence purchasing decisions.

Requirement:

Sticky concentrates create retrieval challenges for consumers, leading to product waste, dosing inconsistencies, and user frustration that negatively impacts brand perception and repeat purchases.

Ghettopac Solution:

Non-stick surface technologies featuring PTFE coatings, silicone linings, and specialty release agents integrated into container construction. Our designs enable complete product extraction while maintaining container reusability and structural integrity throughout product lifecycle.

Requirement:

Cannabis consumers increasingly demand variety packs and sampler options featuring multiple concentrate types in single purchases, requiring packaging that prevents cross-contamination between different consistencies while enabling individual access to each product type without compromising the integrity of remaining concentrates.

Ghettopac Solution:

Our multi-compartment glass jar systems are engineered for cannabis concentrates, featuring individual chambers tailored to different product consistencies—such as sticky live resin, wax, and shatter. Each section is optimized to preserve terpene profiles and THC potency while allowing you to package multiple strains or THC/CBD combinations in a single, unified container.

Legal Compliance Essentials for Cannabis Concentrate Packaging

Child-Resistant Engineering

-

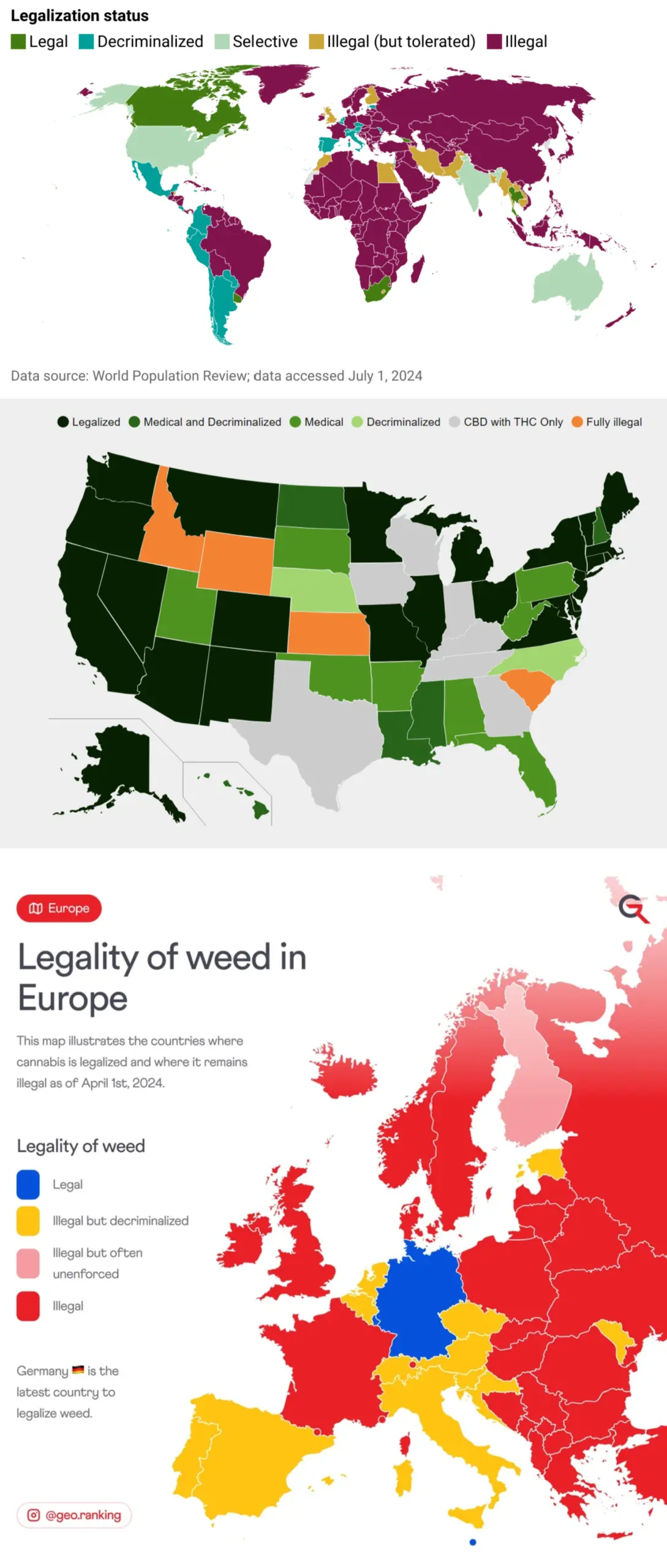

Every state now enforces PPPA/ASTM D3475 protocols: ≥85% of children under five must fail to open the package within 5 min, while ≥90% of able adults succeed.

-

CR performance must persist after 100 open–close cycles when the jar holds more than one serving, a point highlighted in Colorado MED Rule 3-1015 and California CCR §17407.

-

Tamper-Evident Security

-

Shrink bands, break-away rings, or induction liners are mandated so retailers and consumers can see any post-filling breach.

-

California’s 2025 DCC regulations require dispensaries to quarantine any jar whose seal is broken before sale, triggering a METRC discrepancy investigation.

-

Opaque or Light-Blocking Requirements

-

Colorado, Washington, Illinois, New York, and Maryland insist that high-potency concentrates be sold in fully opaque primary containers or in a clear jar placed inside an opaque secondary box or pouch to deter minors and shield THC from UV degradation.

-

If an opaque carton is used, its outer label must still repeat all primary-panel data.

-

Mandatory Label Content

-

Core data—net weight (g), universal cannabis symbol, product identity, manufacturer license, batch/lot, and manufacturing/pack dates—must reside on the primary panel.

-

Potency disclosures differ by state: California demands total THC/CBD and per-package milligrams; Colorado requires per-serving milligrams plus a “Use-By” date ≤9 months unless stability studies justify more.

-

Delayed-onset warning (“effects may be delayed by up to 4 h”) is compulsory on inhalable concentrates in Oregon and on all ingestible concentrates in Colorado. Space-limited jars often use peel-back booklet labels or QR codes for overflow data.

-

Prohibited Marketing Elements

-

No cartoons, neon candy imagery, “organic” without USDA certification, or health claims unsubstantiated by FDA-accepted evidence.

-

Several states bar county or terroir names unless 100% of biomass originates there; violations trigger immediate recall and up to $50,000 fines per SKU in California.

-

Material & Migration Safety

-

Glass, polypropylene caps, silicone gaskets, and any bamboo veneers must meet FDA 21 CFR §177 food-contact rules and document absence of lead, cadmium, phthalates, or PFAS.

-

ASTM E1558 leachate tests at 40 °C/10 days confirm no heavy-metal or plasticizer migration above state limits; results are stored for three years for audit review.

-

Track-and-Trace Integration

-

A scannable unique identifier—barcode, QR, or RFID—must link each jar to METRC, BioTrack, or Leaf Data systems. Initial tag assignment happens at final packaging; any relabel or repackage event must update the UID to maintain chain-of-custody transparency for recalls or tax audits.

-

Sustainability & Post-Consumer Content

-

New York’s Office of Cannabis Management now requires 25% post-consumer recycled (PCR) content in all rigid plastic or mandates a weight-offset fee; California SB 54 will impose similar plastic-reduction targets by 2027. Glass jars with PCR PP lids or ocean-plastic scoops already meet these emerging rules.

-

In-State Lab Certification & Potency Tolerances

-

Colorado and Washington set ±10% THC/CBD potency tolerance between label and COA; Michigan tightened to ±8% in 2025. Any lot outside limits must be relabeled, remediated, or destroyed, and updated labels must carry the new COA reference number.

-

Cross-Border SKU Harmonization

-

Multi-state operators typically design packaging to the strictest common denominator—fully opaque, CR, tamper-evident, with extended content labels—and swap only the state-specific warning panel and tax stamp, easing production yet preserving compliance across diverse statutes.

-

FAQs

What are the most common concentrate types and their requirements?

Popular concentrates include live resin and sauce (requiring glass containers for terpene preservation), shatter and wax (needing non-stick surfaces), distillate (requiring precision dispensing), and rosin (demanding minimal processing contact). Each type requires specific material compatibility and container design considerations.

How do child-resistant requirements apply to concentrate packaging?

Concentrate packaging must meet ASTM D3475 standards with mechanisms difficult for children under five to operate. Orally consumed concentrates require lifetime child-resistance, while inhaled products may use initial-only resistance with appropriate labeling. Single-serving products have additional compliance options.

What materials are safe for cannabis concentrate storage?

Safe materials include glass, food-grade silicone, medical-grade PTFE, and specialized non-reactive plastics like PCTG. Avoid low-grade plastics that may leach chemicals or react with acidic concentrates. Glass remains the gold standard for terpene preservation and chemical inertness.

How can packaging prevent concentrate degradation during storage?

Effective concentrate packaging prevents degradation through UV-blocking materials, airtight sealing systems, temperature-stable construction, and humidity control integration. Black glass, nitrogen-flush compatibility, and barrier films protect against light, oxygen, and moisture exposure.

What's the difference between packaging for different concentrates?

Liquid concentrates require leak-proof sealing and precision dispensing mechanisms, sticky concentrates need non-stick surfaces and wide openings for easy access, while solid concentrates benefit from protective cushioning and secure closure systems. Container design must match product consistency for optimal functionality.

How do labeling requirements differ for concentrates vs flower?

Concentrate labeling must include potency per gram, extraction method, solvent testing results (if applicable), serving size information for measured products, and enhanced warning statements due to high potency levels. Space optimization on smaller containers requires creative labeling solutions.

What are the best eco-friendly options for concentrate packaging?

Sustainable concentrate packaging includes recyclable glass containers, biodegradable mylar options, compostable paper elements, and reusable silicone containers. Some jurisdictions mandate sustainable materials, making eco-friendly packaging both environmentally responsible and compliance-necessary.

How does packaging for infused concentrates differ from traditional extracts?

Infused concentrates often require additional stability considerations for multiple active ingredients, enhanced premium presentation to justify higher pricing, specialized labeling for complex ingredient profiles, and sometimes modified storage requirements based on infusion materials.

How do you select the right concentrate packaging manufacturer?

Choose manufacturers with demonstrated concentrate-specific expertise, understanding of material compatibility requirements, ASTM-certified child-resistant options, customization capabilities for various consistencies, quality control processes for high-value products, and compliance knowledge across multiple jurisdictions. Verify their experience with terpene-preserving materials and non-reactive container construction.