Got Questions?

Throw them at Ghettopac—we’re all ears and ready to roll!

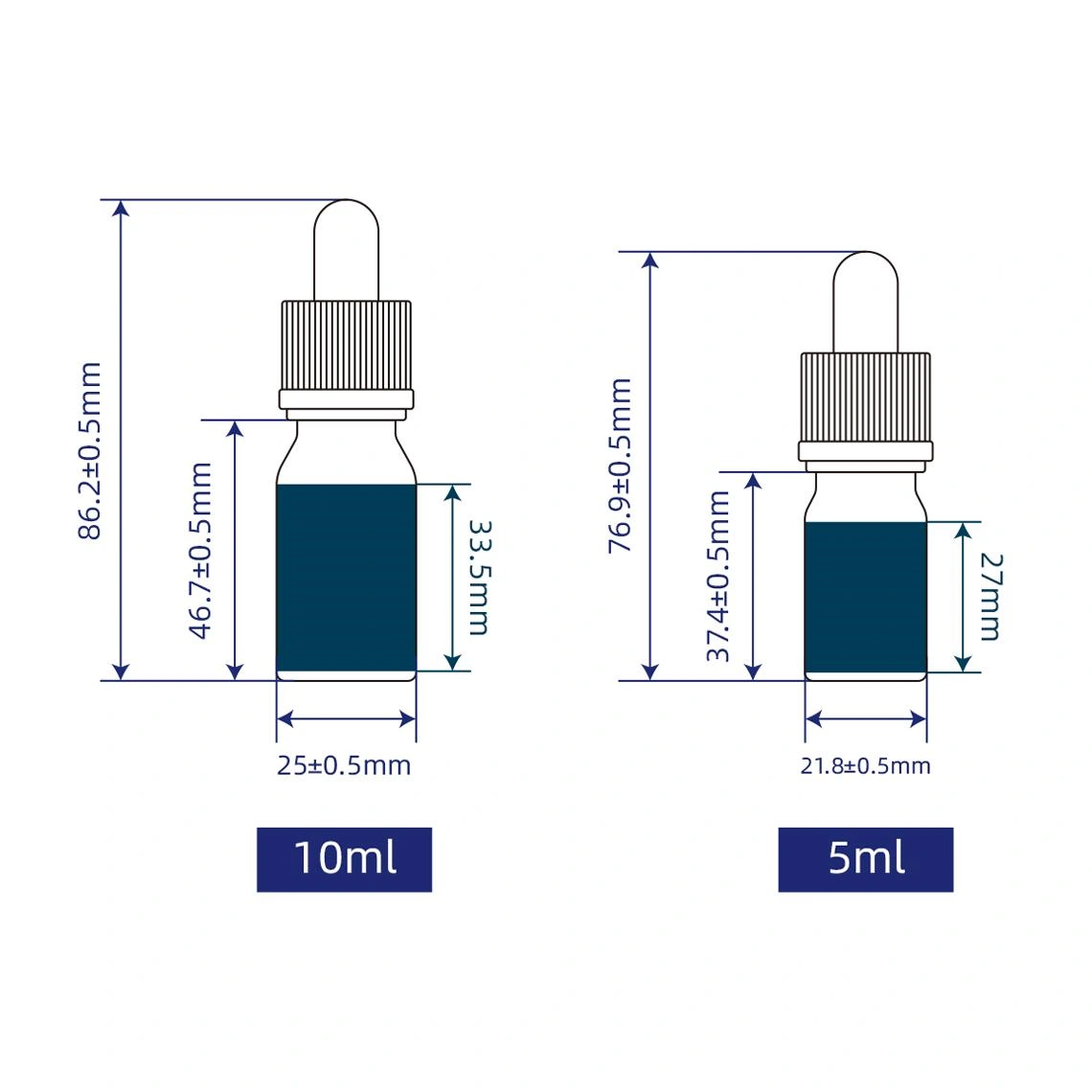

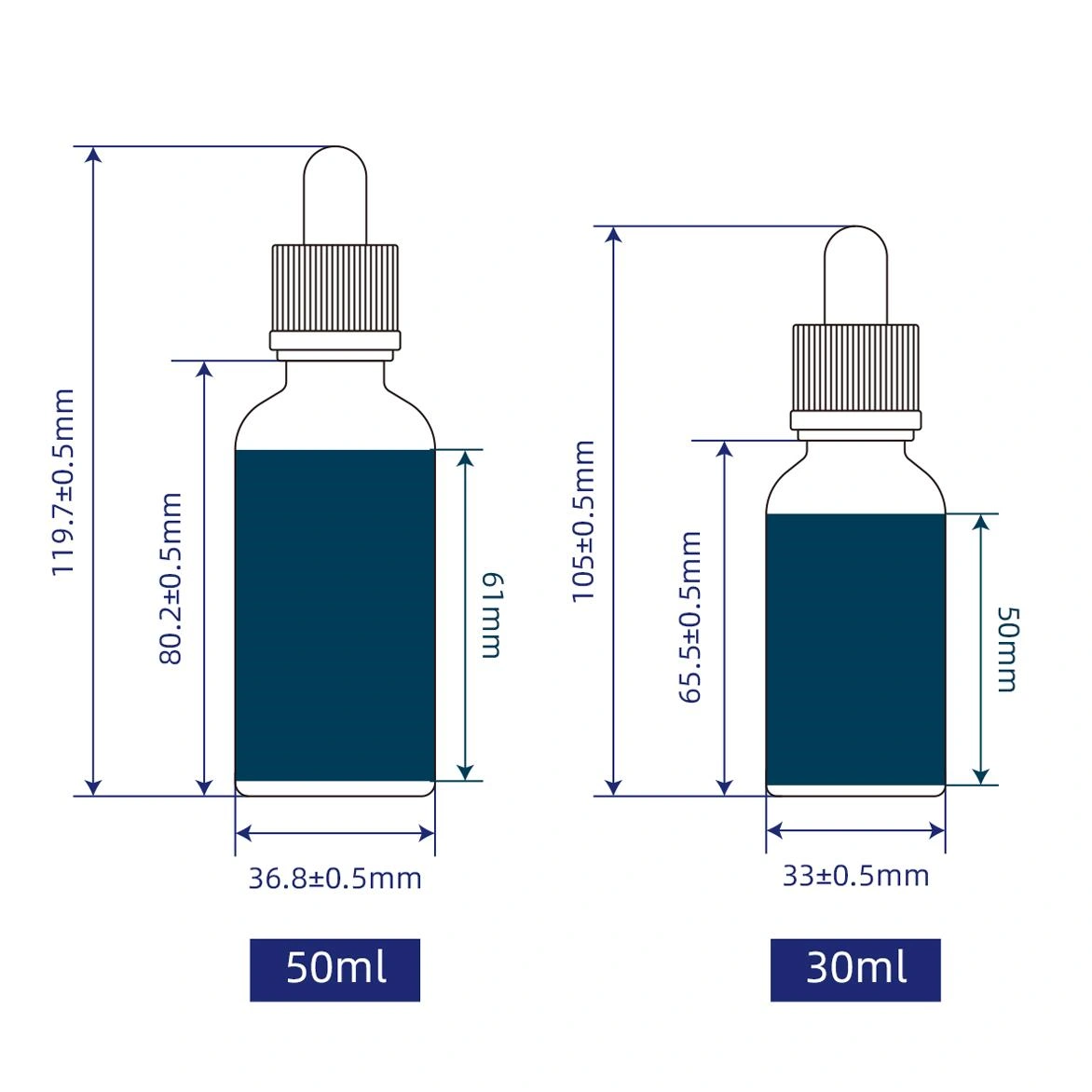

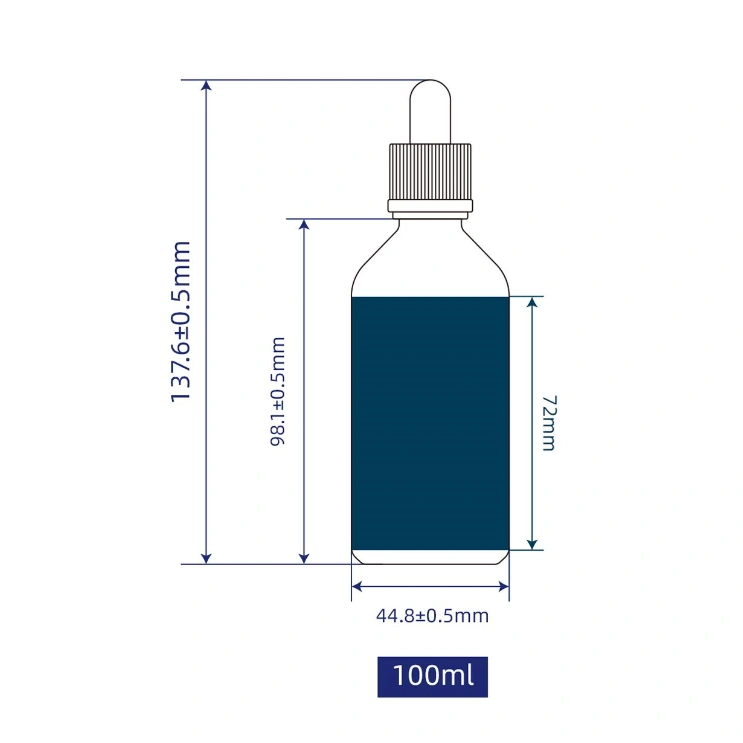

Cannabis dropper bottles are specialized containers equipped with a squeeze bulb and pipette for accurate, controlled dosing of liquid cannabis products such as tinctures and oils. Typical use cases include sublingual consumption, precise topical application, and cannabinoid-rich wellness formulations. Standard volume options include 5ml, 10ml, 15ml, 30ml, and up to 50ml or 100ml for bulk needs.

Precise, metered cannabinoid dosing with calibrated pipette

Discreet, smoke-free sublingual or edible administration route

UV-blocking glass preserves potency, flavor, and terpenes

Child-resistant caps ensure legal compliance and safety

Fast-acting THC/CBD tincture dosing under the tongue

Precision-dosable cannabis oils for culinary infusion recipes

Drop-by-drop application of CBD skincare serums topicals

Portable micro-dosing kits for discreet travel consumption

The bottle, typically glass, safeguards cannabis oils from light and chemical interaction. Its size and neck finish ensure product integrity, precise dosing, and compatibility with various closures.

The choice of glass, particularly amber or cobalt blue, is paramount. These colored glasses are specifically designed to filter out harmful UV light, which can degrade cannabinoids (like THC and CBD) and terpenes, preserving the product’s potency, flavor, and therapeutic effects over time.

While clear glass is sometimes used for aesthetic reasons, it offers less protection and is often paired with secondary packaging to mitigate light exposure. The inert nature of glass also means there’s no risk of chemical leaching into the delicate cannabis oil, unlike some plastics, ensuring product purity.

The range from 5ml to 200ml caters to various product concentrations and consumer needs. Smaller 5ml, 10ml or 15ml bottles might be used for highly concentrated extracts or sample sizes, while the 30ml (1 oz) size is a market standard for tinctures, offering a good balance between a sufficient supply and a compact, portable form factor that fits easily into pockets or purses. Larger 50ml+ bottles are common for products intended for more frequent or higher-dose use.

The standardization of neck finishes (e.g., 18/400, 20/400) is a critical manufacturing and supply chain consideration. The first number refers to the diameter of the bottle opening in millimeters, and the second refers to the thread style.

This standardization ensures that caps and dropper assemblies from different suppliers are interchangeable, providing flexibility for brands in sourcing components and preventing costly compatibility issues during production.

While the cylindrical shape is dominant due to its manufacturing efficiency, stability on shelves, and ease of gripping, some brands opt for square, rectangular, or even custom-molded shapes to create a distinctive brand identity. These unique shapes can enhance shelf appeal but might slightly increase manufacturing costs and require more specialized labeling equipment.

The cap provides crucial child-resistant and tamper-evident security. Often integrated with the dropper, its durable material ensures product safety and maintains the seal’s integrity.

This is not just a feature but a legal requirement in most regulated cannabis markets. The push-and-turn mechanism is the most common design, making it difficult for young children to open while remaining relatively easy for adults. This feature is crucial for public safety and regulatory compliance, demonstrating a brand’s commitment to responsible packaging.

This feature provides an immediate visual indicator to the consumer if the product has been previously opened. It typically involves a plastic ring that detaches from the main cap when first twisted off.

This not only assures product integrity but also helps prevent product tampering or counterfeiting, building consumer trust and complying with industry standards for product security.

Polypropylene (PP) is favored for caps due to its excellent chemical resistance to the various solvents, cannabinoids, and terpenes found in cannabis oils. It’s also durable, relatively inexpensive, and can be molded into complex CR designs.

The design where the cap, bulb, and pipette are sold as a single unit streamlines the filling and capping process for manufacturers. This “all-in-one” approach ensures a consistent fit and seal, reducing the likelihood of leaks and simplifying inventory management compared to sourcing individual components.

The glass pipette, with options of graduated markings, enables precise and safe cannabis oil dosing. Paired with a resilient bulb, it ensures accurate, controlled, and hygienic product delivery.

Glass is the only acceptable material for the pipette itself due to its chemical inertness. Unlike plastic, glass will not absorb, react with, or leach chemicals into the cannabis oil, ensuring the purity and stability of the product. This is particularly important for maintaining the precise concentration of cannabinoids.

The inclusion of volumetric markings directly on the glass pipette is a significant feature for consumer safety. Cannabis dosing can be highly individualized, and these marks (e.g., 0.25ml, 0.5ml, 0.75ml, 1ml) allow users to accurately measure their desired dose, preventing under- or over-dosing and enabling consistent therapeutic effects. This is crucial for products where precise micro-dosing is desired.

The straight-cut tip is standard for general dispensing. However, specialized tapered or bent tips can offer more control, especially for very viscous oils or when a smaller, more precise drop size is needed. Some pipettes also feature a rounded or blunted tip for sublingual (under the tongue) application, making it more comfortable and safer for direct oral use.

Natural rubber or silicone are the preferred materials for the bulb. Both offer excellent elasticity and resilience, allowing for repeated compression and expansion to draw and dispense liquid effectively.

Silicone, in particular, is highly resistant to oils and chemicals, less prone to degradation over time, and can withstand a wider range of temperatures, ensuring the dropper maintains its functionality throughout the product’s use.

The dropper bottle box is for protection, compliance, and branding. It displays vital product information, ensures tamper evidence, and reinforces the brand’s identity and quality.

Typically constructed from durable paperboard or cardstock, the box provides essential physical protection for the fragile glass dropper bottle, safeguarding it from breakage, scratches, and light exposure during transit and storage.

The box serves as the primary surface for mandatory regulatory information, including child-resistant warnings, net content, ingredient lists, batch numbers, manufacturing dates, THC/CBD percentages, and dosage instructions, all crucial for consumer safety and legal compliance.

It acts as a key marketing tool, featuring brand logos, color schemes, and graphic designs that establish brand identity and appeal. Premium finishes like matte coatings, embossing, or spot UV can elevate the product’s perceived value.

Many boxes incorporate tamper-evident seals (e.g., glue tabs, perforated lines, or shrink wrap) that must be broken to access the product, providing an initial layer of security and assuring the consumer that the product has not been opened since packaging.

Choosing the right dropper-bottle volume starts with understanding how concentration, usage frequency, and value intersect. We group sizes into three practical tiers—Small/Trial, Standard/Everyday, and Large/Bulk—to match everything from potent single-dose extracts to economy formats for extended, multi-user routines and consumption.

This category is ideal for highly concentrated products, single-use applications, or as sample/travel sizes.

Product Type: Often used for potent essential oils, concentrated cannabis extracts (e.g., RSO), single-dose medicinal applications, or high-value cosmetic serums.

User Benefit: Allows consumers to try a product without a large commitment, offers extreme portability, and minimizes waste for potent formulations where only a few drops are needed.

Market Use: Common for promotional samples, travel kits, or niche, high-potency products where a full-size bottle would be excessive or too expensive for initial purchase.

This is the most common and versatile category, suitable for regular daily use of various liquid products.

Product Type: The go-to size for cannabis tinctures, CBD oils, vape juice, facial serums, beard oils, and many pharmaceutical drops. The 30ml (1 oz) size is particularly ubiquitous.

User Benefit: Provides a good balance between sufficient product volume for consistent use and a manageable size for daily handling and storage. It’s large enough to last a reasonable period but still portable.

Market Use: Dominates the retail market for most liquid wellness, beauty, and cannabis products due to its practicality and consumer familiarity.

This category is designed for products intended for extended use, professional applications, or bulk purchasing.

Product Type: Often used for massage oils, larger volume cosmetic toners or hair treatments, veterinary supplements, or for cannabis products intended for high-dose users or bulk purchase.

User Benefit: Offers better value per milliliter, reduces the frequency of repurchasing, and is suitable for products consumed in larger quantities or by multiple users.

Market Use: Found in professional settings (e.g., salons, clinics), for economy-sized consumer products, or for specialized industrial/laboratory applications where larger volumes are required. Custom sizes beyond 200ml would fall here, tailored for very specific, often industrial or niche, bulk needs.

Beyond functional sealing, bottle surfaces double as billboards. Coatings, print treatments, and textural effects turn plain glass and cap into a premium touchpoint, attracting eyes in the display case, protecting terpenes from light, and reinforcing sustainability or luxury cues consumers value today.

Opaque lacquer layers tint clear glass any Pantone shade, amplifying brand identity, blocking degrading light, and masking extract residue while keeping internal terpene profile untouched.

Acid-etched or sandblasted frosting diffuses incoming light, reduces finger smudges, and creates a velvety matte feel consumers associate with premium, small-batch extracts for visual elegance.

Silk-screen printing suits simple designs under four colors, offering durability and precision, while digital printing enables complex, multi-color graphics, ideal for detailed, high-impact packaging finishes.

Metallic hot-foil stamping presses gold, silver, or holographic foils into the surface, spotlighting logos and strain names while emphasising luxury and catching budtender lighting angles.

Vacuum electroplating envelops glass in ultra-thin chrome, rose-gold, or rainbow metal, yielding mirror brightness, scratch resistance, and complete light block without adding bulky secondary sleeves.

Bamboo veneer wraps child-resistant lids in fast-renewing wood, delivering a warm eco-luxury aesthetic while cutting visible plastic and signaling sustainability credentials to conscious consumers.

This crucial test verifies that the bottle and dropper assembly form a secure, leak-proof seal. Bottles filled with liquid are inverted, subjected to pressure changes (e.g., vacuum), or placed on their sides for extended periods to detect any drips or seepage. This ensures product preservation and prevents messy consumer experiences.

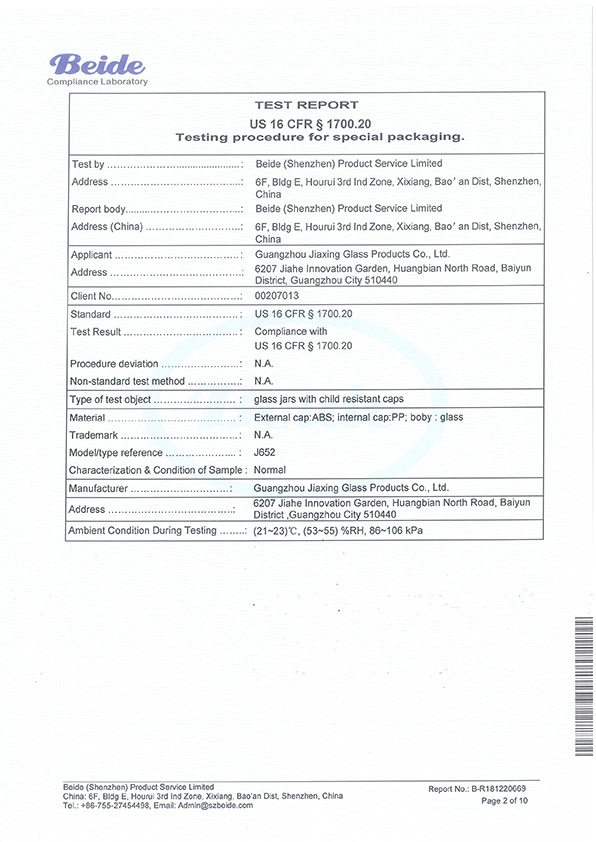

Mandatory for cannabis products, this test assesses if the CR cap meets regulatory standards for preventing access by children while remaining operable for adults. Specialized equipment simulates child attempts to open the cap, ensuring compliance with established protocols like those from the CPSC (Consumer Product Safety Commission).

This test measures the precision of the pipette’s dosage. Using calibrated equipment, the volume of liquid dispensed per drop or per marked increment (e.g., 0.5ml, 1ml) is verified against specified tolerances. This ensures consistent and accurate dosing for consumers, critical for cannabis product efficacy.

Samples of the bottle, cap, and pipette materials are exposed to the cannabis oil formulation (or its components) under various conditions (e.g., temperature, time). This test ensures no degradation, discoloration, or leaching occurs, preventing contamination and maintaining the product’s stability and purity over its shelf life.

Bottles, both empty and filled, are subjected to controlled drops from specified heights onto various surfaces. This test evaluates the bottle’s structural integrity and its ability to withstand typical handling and accidental impacts during shipping, retail, and consumer use, minimizing breakage risks.

Many cannabis droppers feature clear graduation marks (e.g., 0.25ml, 0.5ml, 1ml) directly on the glass pipette. These markings allow users to accurately measure their desired dose, ensuring consistent and controlled consumption. Quality control tests also verify the precision of these measurements during manufacturing.

Yes. Push-down-and-turn caps with ASTM-certified liners meet state cannabis packaging laws, and tamper-evident bands add first-use security; these closures are standard on cannabis dropper assemblies offered by specialized suppliers.

Tinted soda-lime glass blocks up to 99% of UV and visible light, protecting cannabinoids and terpenes from photodegradation; clear glass shows product clarity but needs an outer carton or sleeve to prevent potency loss under light exposure.

Glass is inert, heat-stable, and fully recyclable—ideal for high-terpene, premium oils. PET or HDPE plastic is lighter and shatter-proof for travel kits but can absorb volatiles over long storage, so it suits short-term or sample runs rather than aged concentrates.

Stored upright in a cool, dark place, tinctures in amber or cobalt bottles typically retain labeled potency for 12–18 months; light, heat, and repeated oxygen exposure remain the primary drivers of cannabinoid degradation, so reseal tightly after each use.

State rules require THC/CBD potency, ingredients, batch number, serving size, health warnings, and child-resistant statements; labels must match lab certificates and avoid graphics attractive to minors to pass routine dispensary compliance checks.

While technically possible, it’s generally not recommended, especially for cannabis products. Residue from previous contents might contaminate new products, and proper sterilization can be difficult at home. Reusing could also compromise the integrity of the child-resistant cap or dropper over time, affecting safety and accuracy.

The tamper-evident seal provides a visual indicator if the product has been opened or altered since it left the manufacturer. This feature assures consumers of the product’s integrity and safety, preventing tampering and counterfeiting. It’s a key component of product security and consumer trust.