Glass provides complete chemical inertness that prevents any interaction with cannabis compounds, ensuring THC, CBD, and terpenes maintain their original potency and flavor profiles without degradation from container materials.

Cannabis Edibles

Cannabis edibles represent the fastest-growing segment in legal cannabis markets, offering precise dosing, discreet consumption, and extended effects that appeal to both medical patients and recreational consumers. These professionally manufactured products require sophisticated packaging solutions that protect product integrity, ensure regulatory compliance, and maintain consumer safety while delivering exceptional shelf appeal.

Regulatory Compliance

Moisture Protection

Dosage Safety

Product Visibility Restrictions

Diverse Product Forms

Temperature Sensitivity

From Kitchen to Connoisseur

Advanced Cannabis Edible Packaging Solutions

Requirement:

Cannabis edibles face diverse temperature stability challenges across product formats, with chocolates requiring controlled environments to prevent melting and bloom, while gummies need protection from heat-induced texture changes and cannabinoid degradation during storage and distribution.

Ghettopac Solution:

Thermal barrier packaging systems featuring temperature-stable materials rated for ambient storage conditions, multi-layer insulation films, and reflective barrier technologies that minimize heat transfer and protect against temperature fluctuations during storage and transportation. Our packaging designs incorporate heat-resistant polymers, insulated wall construction, and vapor barrier films that maintain product stability across varying environmental conditions while meeting regulatory opacity requirements.

Requirement:

Edible packaging must accommodate extensive mandatory labeling information including potency data, ingredient lists, allergen warnings, batch tracking, and regulatory symbols within limited surface area while maintaining readable font sizes and proper hierarchy according to state compliance requirements.

Ghettopac Solution:

Optimized labeling designs that maximize available surface area through strategic layout planning, efficient information organization, and clear visual hierarchy systems that accommodate mandatory compliance requirements.

Our compliance templates ensure proper font sizing hierarchy, warning statement prominence, and QR code integration for extended digital compliance while utilizing every available surface area on containers through careful design planning and regulatory information prioritization.

Requirement:

Cannabis edibles require extended shelf stability with controlled moisture, oxygen, and light exposure to prevent mold growth, texture degradation, and cannabinoid breakdown while maintaining food safety standards and preserving terpene profiles throughout 12-24 month shelf lives.

Ghettopac Solution:

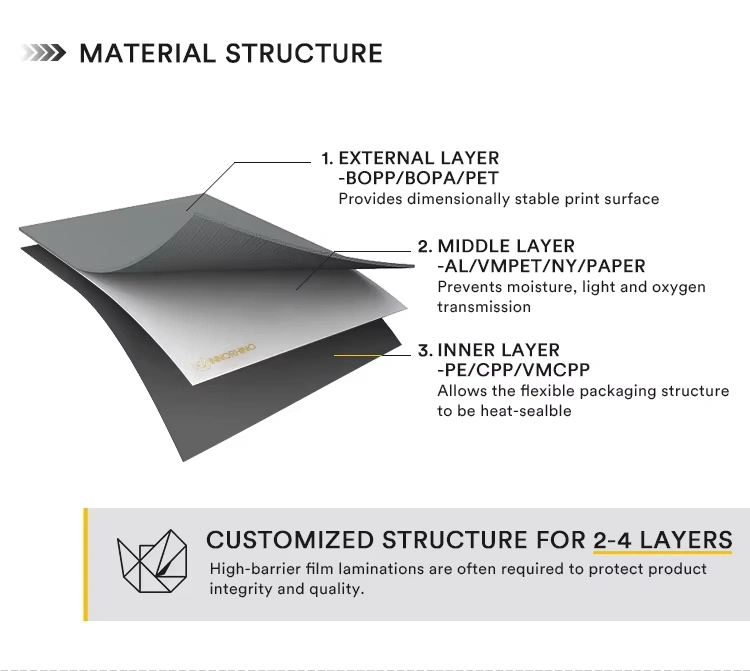

Advanced barrier film technology combining oxygen scavenging systems, moisture-regulating packets, and UV-blocking materials integrated directly into packaging walls for comprehensive product protection. Our freshness preservation systems utilize multi-layer barrier films with specialized coatings that prevent moisture infiltration, oxygen transmission, and light exposure while maintaining optimal internal storage conditions.

Requirement:

Cannabis edible packaging must achieve brand differentiation and premium positioning within severe marketing restrictions that prohibit appealing colors, imagery, or design elements while competing in crowded dispensary environments where traditional visual marketing strategies are prohibited.

Ghettopac Solution:

Sophisticated tactile branding systems utilizing embossed textures, premium material selection, and innovative structural designs that communicate quality through touch and form rather than visual appeal. Our compliant differentiation strategies include subtle metallic accents, unique closure mechanisms, and soft touch glass jar coatings with matte spray finishes that provide velvety, rubbery handfeel creating memorable brand experiences within regulatory boundaries.

Requirement:

Premium concentrate products command high margins but require packaging that communicates quality, potency, and craftsmanship to justify pricing and differentiate from lower-tier offerings in crowded dispensary displays.

Ghettopac Solution:

Luxury finishing techniques including soft-touch coatings, holographic security features, precision embossing, and custom color-matching. Our premium materials and sophisticated design elements create memorable shelf presence while highlighting product quality indicators that influence purchasing decisions.

Requirement:

Sticky concentrates create retrieval challenges for consumers, leading to product waste, dosing inconsistencies, and user frustration that negatively impacts brand perception and repeat purchases.

Ghettopac Solution:

Non-stick surface technologies featuring PTFE coatings, silicone linings, and specialty release agents integrated into container construction. Our designs enable complete product extraction while maintaining container reusability and structural integrity throughout product lifecycle.

Requirement:

Cannabis consumers increasingly demand variety packs and sampler options featuring multiple concentrate types in single purchases, requiring packaging that prevents cross-contamination between different consistencies while enabling individual access to each product type without compromising the integrity of remaining concentrates.

Ghettopac Solution:

Our multi-compartment glass jar systems are engineered for cannabis concentrates, featuring individual chambers tailored to different product consistencies—such as sticky live resin, wax, and shatter. Each section is optimized to preserve terpene profiles and THC potency while allowing you to package multiple strains or THC/CBD combinations in a single, unified container.

Legal Compliance Essentials for Cannabis Edible Packaging

ASTM and PPPA Certification Standards

All cannabis edibles must be packaged in child-resistant packaging that meets federal Poison Prevention Packaging Act (PPPA) standards, requiring 85% child-resistant effectiveness without demonstration and 80% effectiveness after demonstration for children under five years old.

Three Approved Child-Resistant Categories

California recognizes three types of qualifying child-resistant packaging: PPPA-certified containers with official testing documentation, bottles sealed with pry-off metal crown cork-style caps for single servings, and plastic packaging at least 4 mils thick with heat-sealing without easy-open features.

Single-Use vs. Lifetime Resistance

Packaging must specify whether it maintains child resistance after opening (“Lifetime CRP”) or loses resistance once opened (“Initial CRP”), with single-use packages requiring specific labeling stating “This package is not child-resistant after opening”.

Mandatory Labeling Information

Primary Panel Requirements

Cannabis edible labels must display product identity clearly identifying the item as “Cannabis-Infused,” universal symbol measuring at least 0.5″ x 0.5″ in black, net weight in both metric and U.S. customary units, and THC content per serving and per package prominently featured.Information Panel Compliance

Required information includes manufacturer contact details, UID tracking number from state track-and-trace systems, government warning statements, batch numbers, ingredient lists with allergen disclosures, expiration dates, usage instructions, and testing facility information.Potency and Serving Limitations

California limits edibles to maximum 10mg THC per serving and 100mg THC per package for adult use, with clear labeling required for both per-serving and total package cannabinoid content including THC and CBD levels.Proposition 65 Compliance Requirements

Updated Warning Requirements (2024-2025)

California’s Proposition 65 now requires specific warnings for cannabis edibles containing THC, which is listed as causing reproductive harm, and cannabis smoke exposure warnings for certain product categories.Tailored Cannabis Warnings

Effective October 2022 with a one-year phase-in period, cannabis products must display tailored Prop 65 warnings stating exposure to chemicals including β-myrcene, cannabis smoke, and Delta-9-tetrahydrocannabinol known to cause cancer, birth defects, or reproductive harm.Current Enforcement Trends

2025 has seen increased Prop 65 enforcement with over 1,385 violation notices issued through April, targeting cannabis operators for inadequate warning compliance on topicals, vapes, oils, and edibles.Universal Symbol and Visual Requirements

Standardized Universal Symbol

All cannabis edible packages must display California’s official universal cannabis symbol on the primary panel, measuring minimum 0.5″ x 0.5″, printed in black, and accompanied by specific warning statements as mandated by state regulations.Opaque Packaging Mandate

Cannabis edibles must be packaged in completely opaque containers that prevent product visibility, eliminating any chance for children to see appealing food products inside while maintaining regulatory compliance.Product Stamping Requirements

Certain edible formats including chocolates, soft confections, hard candies, and baked goods must have the universal symbol stamped, marked, or imprinted directly onto individual products, with size requirements based on product dimensions.Extended Producer Responsibility (EPR)

California’s SB 54 Plastic Pollution Prevention Act became effective in 2025, requiring cannabis brands to participate in Extended Producer Responsibility programs for packaging materials, with no exemption for cannabis operators.

Enhanced Environmental Requirements

New regulations require cannabis packaging to meet sustainability standards, with manufacturers responsible for end-of-life packaging management and compliance with California’s ambitious plastic reduction targets.

Federal Rescheduling Considerations

While cannabis remains federally scheduled, ongoing rescheduling discussions may impact future packaging requirements, though current state-level compliance obligations remain fully in effect regardless of federal scheduling changes.

Multi-State Expansion Requirements

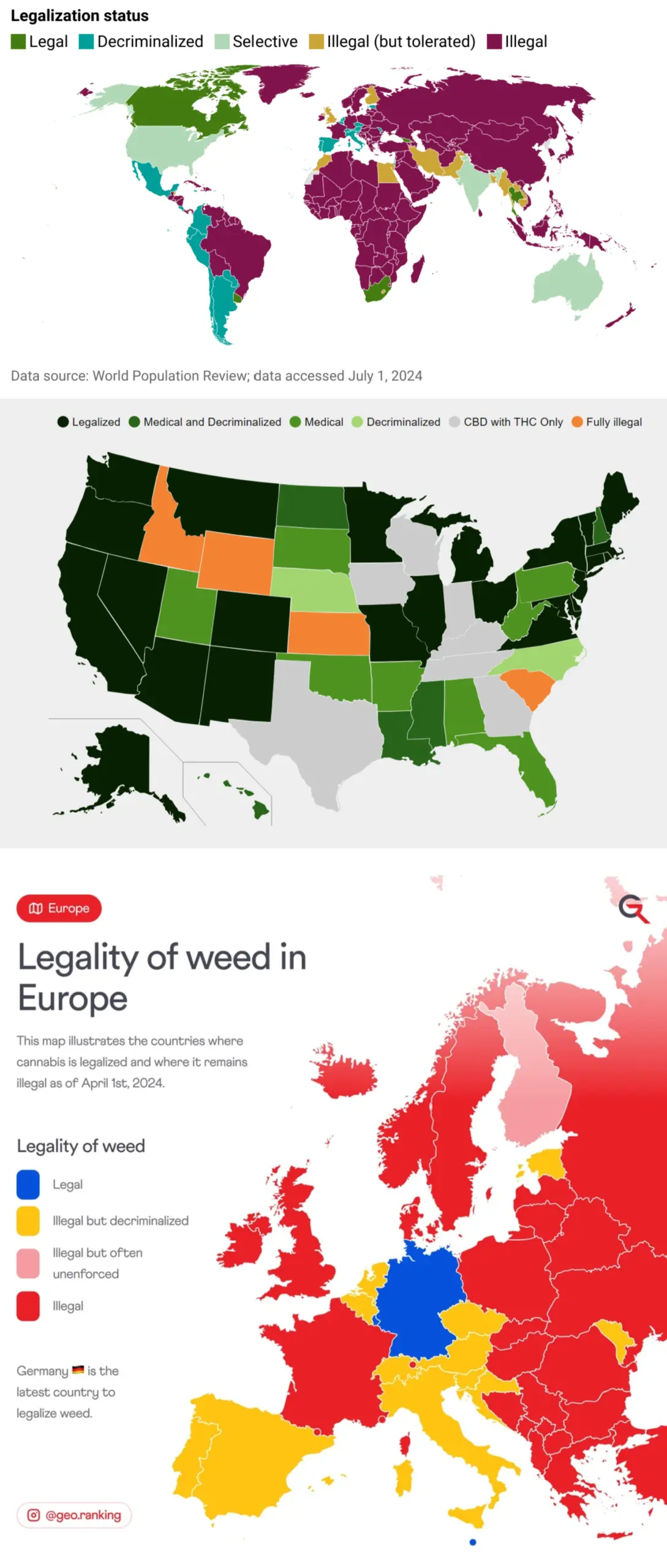

New legal markets in Kentucky, Virginia, Hawaii, Indiana, and Tennessee are implementing packaging requirements similar to established markets, creating opportunities for compliant packaging solutions across expanding legal jurisdictions.

FAQs

What are the mandatory requirements for cannabis edible packaging?

Cannabis edible packaging must be child-resistant, tamper-evident, opaque, and resealable for multi-serving products. State regulations also require specific labeling including THC/CBD content, warnings, and tracking information while prohibiting product images and child-attractive designs.

How do child-resistant requirements differ for edibles versus other cannabis products?

Edible packaging must meet the same ASTM standards but faces additional challenges due to diverse container shapes and the need for opaque barriers. Multi-serving edibles require resealable child-resistant features that maintain functionality through repeated use cycles.

Why must edible packaging be completely opaque?

State laws require opaque packaging to prevent accidental consumption by reducing visual appeal to children and eliminating confusion with regular food products. This includes prohibiting product photos and requiring solid barriers that completely obscure contents.

What labeling information is mandatory for cannabis edibles?

Required information includes THC/CBD content, serving sizes, universal cannabis symbols, government warnings, batch tracking, testing lab information, and allergen declarations. Font sizes and warning prominence are strictly regulated by state authorities.

How do you ensure freshness and potency in edible packaging?

Proper edible packaging incorporates moisture barriers, oxygen absorbers, and airtight sealing systems that maintain optimal storage conditions. UV-protective materials and temperature-stable designs preserve cannabinoid integrity throughout shelf life.

What are the restrictions on edible package design?

Packaging cannot include cartoons, bright colors, or designs that appeal to children. The word “candy” is prohibited, and packages cannot resemble commercially available snack foods. All designs must clearly communicate that products contain cannabis.

How do you choose between flexible and rigid packaging for edibles?

Consider product characteristics, serving sizes, and brand positioning. Rigid containers offer premium presentation and better protection for multi-serving products, while flexible pouches provide cost efficiency for single servings and space-efficient storage.

How do sustainability requirements impact cannabis edible packaging choices?

California’s SB 54 Extended Producer Responsibility Act now requires cannabis brands to participate in packaging sustainability programs without exemption, making environmental compliance mandatory alongside safety requirements. Sustainable edible packaging options include hemp-based materials, recycled content containers, and designs that minimize plastic usage while maintaining child-resistant and tamper-evident functionality.

Many states are implementing similar environmental regulations, so choosing packaging materials that meet both safety and sustainability standards helps ensure long-term compliance. Work with packaging suppliers who can provide documentation of recyclable content and participate in EPR programs to avoid future compliance issues and potential fines.