Got Questions?

Throw them at Ghettopac—we’re all ears and ready to roll!

Cannabis flower contains the highest concentrations of cannabinoids and terpenes that define each strain’s unique therapeutic and recreational properties. Ghettopac’s specialized flower jars are engineered for optimal cannabis flower preservation, delivering airtight sealing technology that prevents cannabinoid degradation while maintaining precise humidity levels essential for flower quality. Our glass containers provide chemical inertness and UV protection that preserve delicate terpene profiles, ensuring your premium cannabis flower maintains its full potency from cultivation to consumption.

Preserve cannabinoids and terpenes from harmful light and oxidation

Maintain humidity levels between 55-62% with 2-Way Humidity Control Gasket

Create airtight seals preventing contamination and unwanted moisture intrusion

Block harmful UV radiation with UV-proof black and ultraviolet jars

Medical cannabis dispensaries requiring patient product storage solutions

Recreational retail operations needing attractive brand-compliant packaging

Commercial cultivation facilities for curing and bulk storage operations

Consumer home storage maintaining freshness and potency preservation needs

Glass jars are a classic and reliable option for cannabis storage, prized for their ability to preserve the flower’s flavor and potency by providing a stable and inert environment. They offer a premium feel and a clean, sleek look that can enhance the perceived value of the product.

Glass is a chemically non-reactive material, ensuring that it will not leach any chemicals or odors into your cannabis. This non-porous and impermeable quality preserves the original flavor, aroma, and overall purity of the flower, providing a superior sensory experience for the consumer.

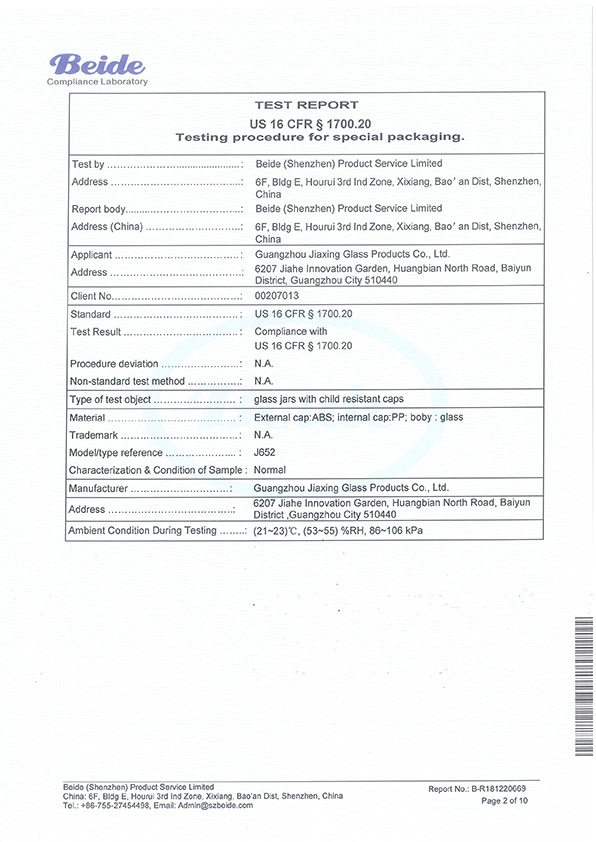

Equipped with a child-resistant push-and-turn screw cap, this closure system prevents children from accessing the contents while ensuring an airtight seal to preserve product freshness. Certified under ASTM D3475, the mechanism integrates seamlessly into jar designs, maintaining full regulatory compliance while remaining accessible for adult consumers.

While classic clear glass is widely used, these jars can be customized with a variety of decorative finishes. Options such as matte, frosted, glossy, or custom-printed designs enhance brand differentiation and visual appeal, providing a more discreet and personalized presentation compared to standard transparent glass.

Glass jars can be paired with child-resistant caps featuring decorative outer finishes such as bamboo and wood, offering consumers a natural and eco-friendly aesthetic. Each closure is designed with poly liners to create a secure barrier against oxygen and moisture, providing enhanced product protection while elevating overall shelf appeal.

Plastic jars offer a lightweight and cost-effective solution for storing cannabis. While not always ideal for long-term preservation compared to glass, they provide a convenient and portable option for short-term storage and are less prone to breaking.

Due to their significantly lower weight compared to glass, plastic jars are much more convenient to carry and transport. This makes them an excellent choice for consumers who need a portable storage solution for taking their cannabis on the go without the bulk and weight of glass.

Plastic jars are generally more affordable and widely available than their glass counterparts. This cost efficiency makes them a practical and budget-friendly packaging choice for both consumers and dispensaries looking for an economical storage solution.

One of the main advantages of plastic is its resilience; it is shatterproof and will not break if dropped. This durability makes plastic containers a reliable option for various situations, especially for those concerned about the fragility and potential breakage of glass jars.

The versatility of plastic allows for a wide range of container designs tailored to different consumer needs and product types. For instance, “pop-top” vials offer unparalleled convenience with their squeeze-to-open hinged lids, making them ideal for frequent, quick access. In contrast, threaded screw-top jars provide a more robust and secure closure, creating a tighter seal that is better for short-term preservation of freshness and odor control, offering consumers flexibility for both on-the-go use and at-home storage.

UV-proof black jars are specifically designed to protect cannabis from the harmful effects of light, which can degrade its quality over time. This ensures maximum preservation of potency, flavor, and the therapeutic and aromatic properties of the flower.

The opaque, black-coated glass acts as a vigilant guardian, effectively blocking harmful ultraviolet (UV) light rays. This protection is critical because UV light degrades sensitive cannabinoids like THC and terpenes, and preventing this exposure preserves the flower’s potency and quality for extended periods.

These jars are engineered to feature a secure, airtight seal that prevents oxygen and moisture from entering. By keeping the environment inside the jar stable, the seal helps to maintain the flower’s freshness, prevent it from drying out, and inhibit mold growth.

The combination of a non-porous glass construction and a tightly sealed lid effectively traps the strong and pungent aroma of cannabis inside the jar. This makes them a smell-proof solution, preventing unwanted odors from escaping and ensuring discretion.

Typically made from thick, high-quality glass, these jars are built for longevity and are less likely to break than standard glass. This durable design ensures they can be reused consistently, offering a reliable and long-lasting storage solution for protecting your flower.

Ultraviolet jars are made from a special type of pigmented glass, often appearing deep violet or black, that offers superior protection for cannabis. It works by filtering out damaging light rays while allowing beneficial ones to pass through, preserving and enhancing the contents.

This specialized violet glass is designed to block the complete spectrum of harmful visible light that accelerates molecular decay. Simultaneously, it allows beneficial UV-A and infrared light to penetrate, which can help inhibit the growth of molds, algae, and bacteria.

By preventing the degradation of cannabinoids and terpenes caused by harmful light, UV jars are proven to maintain the flower’s potency, flavor, and aroma for extended periods, keeping it fresh for six months to a year.

Constructed from durable and high-quality glass, these jars are designed for repeated use, making them a sustainable and environmentally friendly alternative to single-use plastic packaging. Their longevity offers a cost-effective solution over time.

Select jar designs include a built-in hygrometer on the cap, enabling real-time monitoring of internal humidity and temperature. While it does not regulate conditions, this feature provides valuable visibility to help maintain optimal storage and protect cannabis flower quality throughout its shelf life.

An airtight storage jar is a container defined by its primary function: creating a superior seal to protect cannabis from the degrading effects of air and moisture. The focus is on the closure mechanism, which ensures the preservation of the flower’s freshness, aroma, and potency, regardless of the jar’s specific material.

The core purpose of the airtight seal is to minimize the flower’s exposure to oxygen. This is critical because oxygen is a primary driver in the degradation of cannabinoids like THC and terpenes. Limiting air exchange directly preserves the potency and intended effects of the cannabis.

A secure seal is crucial for maintaining a stable and ideal humidity level inside the container. It prevents the flower from drying out and becoming brittle while also protecting it from excess ambient moisture that could lead to mold, ensuring the product’s quality and longevity.

airtight jars come in diverse styles to suit different preferences. They range from classic clear glass jars paired with organic bamboo lids for a natural aesthetic, to modern designs featuring sleek, durable brushed metal or stainless steel caps, offering a more premium and contemporary look.

The effectiveness of these jars lies in their closure designs. Many utilize a friction-fit seal created by a flexible silicone gasket on the inside of the bamboo or metal lid. Other modern styles, particularly for smaller quantities, might use vibrant, flexible silicone lids that stretch over the jar’s opening or feature snap-on caps for a secure and convenient closure.

Powered by ATMOSIScience® fiber technology, this advanced gasket is not just a simple seal but an active atmospheric control system integrated into a liner. It is engineered to create the perfect microclimate inside a storage jar, ensuring cannabis flower is preserved at peak quality.

At its core is a multi-layer design featuring a sealer layer, a breathable layer, and an inner core of 2-way Humidity Control BambooFiber. This salt-free, liquidless system, crafted from natural bamboo and wood fibers, automatically regulates humidity by absorbing or releasing moisture to maintain a stable environment.

The gasket’s active 2-way control is a powerful defense against common storage problems. It prevents the flower from absorbing too much moisture, which can lead to mold, while also keeping it from drying out, which causes a harsh texture and loss of potency.

This system is designed as a liner that can be heat-sealed directly onto the jar’s rim before the lid is applied. This creates a tamper-evident, airtight barrier that provides a certified child-resistant seal, locking in freshness and security from the point of packaging.

The gaskets offer extensive opportunities for branding and aesthetic customization. As shown with the “Jarsking” examples, the surface can be printed with any color, pattern, or logo, allowing premium brands to integrate their visual identity directly into the packaging’s preservation technology.

Paper boxes serve as a premium secondary packaging solution, designed to protect the inner flower jar while providing ample space for branding and regulatory information. They elevate the unboxing experience and enhance the product’s overall shelf appeal.

A well-designed paper box often includes a custom-fitted inner tray or insert made from paperboard or foam. This insert holds the flower jar securely in place, preventing it from shifting during transit and protecting the fragile glass or plastic from scratches, impacts, and breakage.

The exterior surface of a box offers a large canvas for high-quality printing, branding, and storytelling. It allows companies to display their logo, brand colors, and unique designs, creating a strong visual identity that stands out on competitive dispensary shelves and attracts consumer attention.

Paper boxes provide the necessary space to clearly print all legally required information, which may not fit on the jar itself. This includes strain name, weight, cannabinoid profiles (THC/CBD content), batch numbers, QR codes for lab results, and government-mandated warnings.

A custom box transforms a simple jar into a premium product, improving the unboxing experience for the customer. It adds a layer of professionalism and perceived value, suggesting a higher quality product inside and building brand loyalty.

The capacity of a cannabis flower jar is specifically tailored to its intended purpose and user. From small, single-purchase retail containers to large-scale commercial storage solutions, each size category prioritizes different features—whether it’s branding and child-safety for consumers or long-term preservation and durability for cultivators and connoisseurs.

This category represents the most common sizes available to the end consumer and is the primary focus for retail packaging at dispensaries. Jars in this range are designed to hold standard market quantities, from an eighth (3.5g) or a quarter (7g) up to a full ounce (28g) or more.

Primary User: Individual consumers, medical patients, and tourists purchasing from a dispensary.

Key Focus: The emphasis is on a balance of product preservation, branding, and regulatory compliance. These jars must be appealing on the shelf, keep the product fresh for a few weeks to a couple of months, and, most importantly, feature certified child-resistant closures as required by law in most regions.

Common Features: This is where you see the widest variety of materials and decorative finishes—from clear, frosted, or matte black glass to cost-effective plastic. The packaging is a critical marketing tool, often featuring high-quality printing, custom colors, and unique lid materials like bamboo or brushed metal to convey a premium brand image.

This mid-range category serves the needs of cannabis aficionados, home cultivators, and medical patients with larger allotments. These capacities are too large for a typical single purchase but are perfect for storing a significant personal supply or the yield from a small-scale harvest.

Primary User: Serious cannabis enthusiasts, home growers, and medical patients.

Key Focus: The absolute priority for this category is long-term preservation. The goal is to cure the flower properly and maintain its potency, terpene profile, and ideal humidity for months. Aesthetics and branding are secondary to pure functional performance.

Common Features: Jars in this group are almost always made of high-quality, thick glass, with a strong preference for UV-blocking options like opaque black or ultraviolet (violet) glass to prevent light degradation. They feature superior airtight sealing mechanisms, such as glass lids with clamps and rubber gaskets, and are often used in conjunction with 2-way humidity control packs or integrated gaskets to ensure a perfect storage environment.

These large-format containers are the workhorses of the commercial cannabis industry, designed for back-of-house operations and business-to-business transport. Their purpose is to safely store and handle bulk quantities of flower after it has been harvested and cured but before it is packaged for retail sale.

Primary User: Cultivators, processors, testing labs, and dispensary inventory managers.

Key Focus: Efficiency, durability, and maximizing preservation on a large scale. These containers must be robust, easy to handle, and provide an excellent seal to protect a significant financial investment in product. Stackability and ease of access (e.g., wide mouths) are also important practical considerations.

Common Features: While very large glass jars exist, this category often includes other materials like food-grade stainless steel, which is unbreakable, completely lightproof, and easy to sanitize. Lids are heavy-duty with silicone gaskets to ensure a truly airtight seal. “Custom” sizes are most relevant here, as a commercial producer might order containers with specific dimensions to perfectly fit their vault shelving or processing equipment.

Beyond functional sealing, marijuana jar surfaces double as billboards. Coatings, print treatments, and textural effects turn plain glass and cap into a premium touchpoint, attracting eyes in the display case, protecting terpenes from light, and reinforcing sustainability or luxury cues consumers value today.

Opaque lacquer layers tint clear glass any Pantone shade, amplifying brand identity, blocking degrading light, and masking extract residue while keeping internal terpene profile untouched.

Acid-etched or sandblasted frosting diffuses incoming light, reduces finger smudges, and creates a velvety matte feel consumers associate with premium, small-batch extracts for visual elegance.

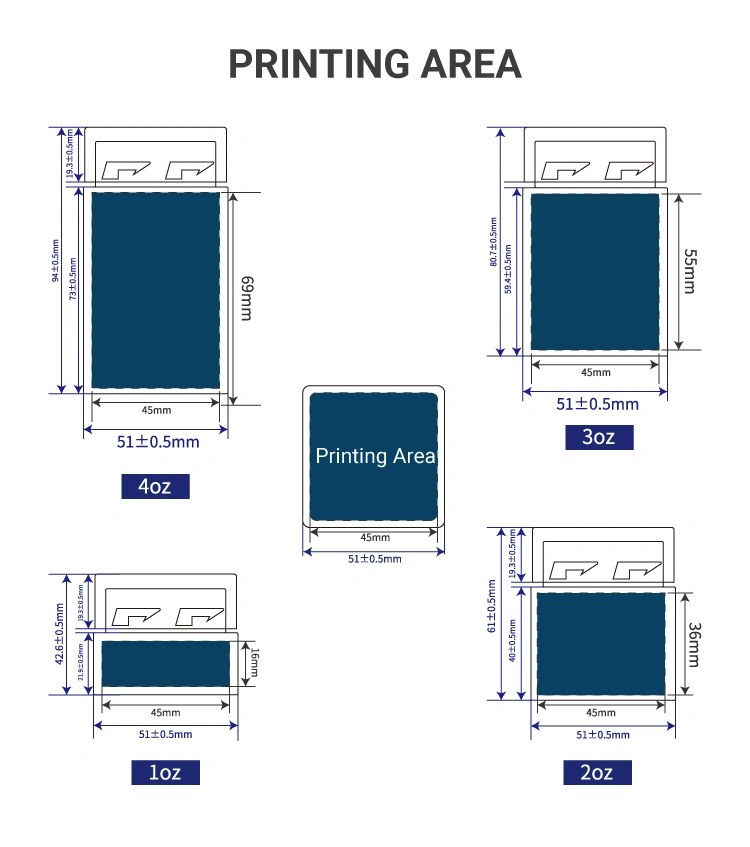

Silk-screen printing offers unmatched durability for bold logos and text. It uses thick ink layers for precise, tactile designs, making it ideal for simple graphics under four vibrant colors.

Digital printing directly applies ink to the jar, allowing for unlimited colors and photo-realistic detail. It is perfect for complex, vibrant graphics, gradients, and detailed, high-impact artwork.

Water transfer printing applies a continuous, 360-degree graphic by immersing the jar in a patterned film. It achieves seamless, photorealistic finishes, ideal for complex, all-over designs.

Labeling is the most versatile and cost-effective option, using applied stickers for branding. It allows for easy application of variable data and premium finishes like metallic foils or embossing.

Metallic hot-foil stamping presses gold, silver, or holographic foils into the surface, spotlighting logos and strain names while emphasising luxury and catching budtender lighting angles.

Vacuum electroplating envelops glass in ultra-thin chrome, rose-gold, or rainbow metal, yielding mirror brightness, scratch resistance, and complete light block without adding bulky secondary sleeves.

Bamboo veneer wraps child-resistant lids in fast-renewing wood, delivering a warm eco-luxury aesthetic while cutting visible plastic and signaling sustainability credentials to conscious consumers.

Child-resistance mechanisms undergo rigorous testing using standardized ASTM D3475 protocols involving 50 children aged 42-51 months attempting to open packages within 5 minutes, with 85% failure rate required. Adult accessibility testing with 100 participants aged 50-70 ensures at least 90% can successfully open containers within one minute, balancing safety with usability.

Vacuum decay testing measures container integrity by creating negative pressure and monitoring pressure changes over time, ensuring hermetic sealing prevents oxygen infiltration that degrades cannabinoids. Helium leak detection identifies microscopic seal failures, while repeated open-close cycle testing verifies gasket performance through 200+ operations maintaining consistent seal effectiveness for long-term storage reliability.

Water vapor transmission rate (WVTR) testing measures permeability using gravimetric methods per ASTM F1249 standards, ensuring containers maintain optimal 55-62% relative humidity levels. Humidity control validation involves storing calibrated humidity sensors inside sealed jars with moisture control packets, monitoring stability over 30-day periods under varying environmental conditions.

Drop testing from standardized heights (1.5-3 meters) onto concrete surfaces evaluates structural integrity under shipping and handling stress conditions. Compression testing applies 200-500 pound loads measuring deformation resistance, while thermal shock testing subjects containers to rapid temperature changes (-20°C to +50°C) ensuring performance across distribution environments.

Peel strength testing measures label adhesion force using universal testing machines, ensuring regulatory compliance labels remain attached throughout product lifecycle. Environmental stress testing subjects labeled containers to humidity chambers (90% RH), temperature cycling, and UV exposure, validating label integrity and readability under storage and display conditions.

Temperature cycling subjects containers to repeated heating and cooling cycles between -20°C to +50°C measuring structural integrity, seal performance, and material stability. Testing evaluates thermal expansion effects on gasket compression, lid torque retention, and potential container cracking under distribution temperature variations. Critical for maintaining airtight seals through seasonal temperature changes during transportation and storage.

Accelerated aging exposes packaging to elevated temperature (40°C), humidity (75% RH), and UV radiation simulating months of storage in accelerated timeframes. Testing identifies material degradation, color changes, label adhesion failure, and seal compromise before products reach market. Validates packaging performance across expected shelf life under worst-case storage conditions while maintaining regulatory compliance standards.

Cannabis flower jars are specialized packaging containers designed to preserve cannabinoids, terpenes, and overall flower quality during storage and distribution. The main purpose is to protect cannabis from its four natural enemies: light, temperature, humidity, and air exposure. Proper packaging ensures cannabis remains neither too damp nor too dry, free from mold and contaminants, while maintaining appropriate flavor and potency.

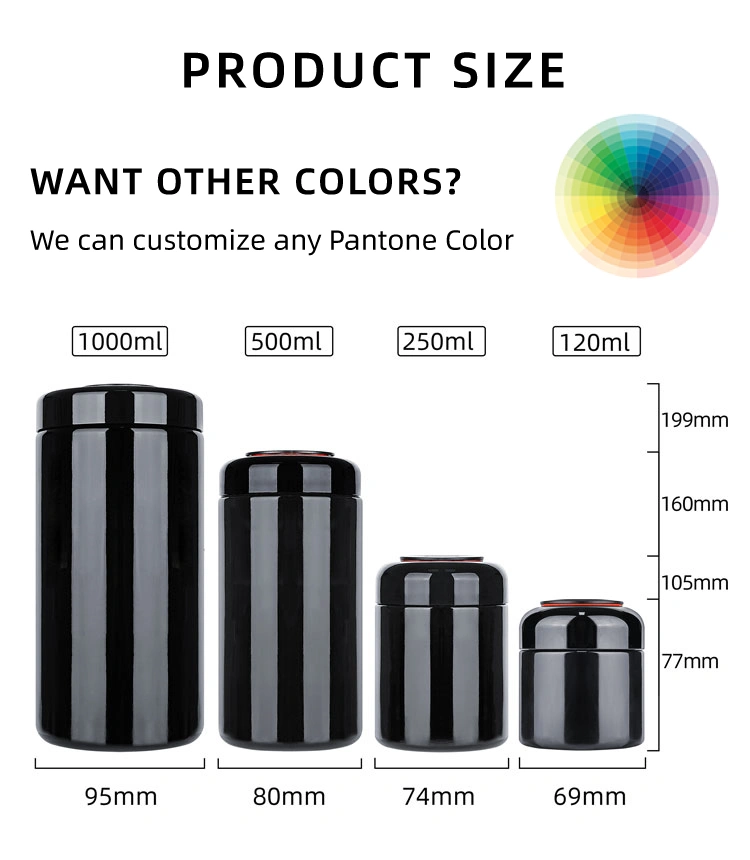

Cannabis flower capacity varies based on density, moisture content, and whether buds are whole or ground. Standard capacities include:

15ml (0.5oz): 0.5-1 gram

30ml (1oz): 1-2 grams

60ml (2oz): 3.5 grams (eighth ounce)

120ml (4oz): 7-10 grams (quarter ounce)

180ml (6oz): 14 grams (half ounce)

240ml (8oz): 28 grams (full ounce)

A two-ounce jar doesn’t necessarily hold two ounces of cannabis by weight. Volume measurements refer to liquid capacity, while cannabis is sold by weight. The actual amount depends on bud density, moisture content (optimal 10-15%), and whether flower is whole or ground. Dense indica strains pack tighter than fluffy sativa varieties.

Glass jars offer superior preservation with chemical inertness, airtight sealing, UV protection (amber/violet tinted), and reusability. They’re ideal for premium products and long-term storage, maintaining flavor profiles without leaching chemicals.

Plastic jars provide cost-effective moisture barrier protection with impact resistance, integrated child-resistant mechanisms, and competitive pricing for high-volume operations. They’re perfect for budget-conscious brands and reduce shipping costs due to lightweight construction.

UV-proof black jars provide complete light blocking through opaque construction, preventing all cannabinoid degradation and meeting state opacity requirements for discrete storage.

Ultraviolet (violet) jars use biophotonic technology that filters harmful visible light while allowing beneficial UV and infrared rays to naturally preserve flower and prevent microbial growth. This glass extends shelf life significantly compared to clear or amber alternatives.

ATMOSIScience® fiber-based 2-Way Humidity Control Gaskets featuring multi-layer construction with sealer, breathable, and bamboo fiber core layers that automatically regulate humidity through salt-free, liquidless natural fiber technology.

This revolutionary gasket system maintains precise 55-62% relative humidity through ±2% RH precision while eliminating static electricity that causes trichome loss, providing up to 12 months of freshness without requiring humidity pack replacements.

Cannabis jars must include tamper-evident features providing unmistakable visual confirmation of package integrity. Options include heat-induction seals, breakaway bands, and destructible closures that break cleanly upon first opening while remaining attached during normal handling.

Opacity requirements vary by state. Some jurisdictions mandate fully opaque packaging to reduce product visibility, while others allow clear containers. Our jars accommodate varying requirements through opaque options, selective opacity features, and clear containers for states permitting product visibility.

Cannabis flower requires 55-62% relative humidity to prevent mold growth and terpene degradation. Storage temperature should be approximately 70°F (21°C) in cool, dark conditions. Higher temperatures dry out cannabinoids and terpenes, while temperature fluctuations create condensation leading to mold.

With proper storage in airtight, UV-protected containers, cannabis products maintain potency between one and two years according to the Journal of Pharmacy and Pharmacology. Nitrogen-purged packaging maintains freshness for 12+ months by eliminating oxygen that converts THC to CBN. Proper humidity control and light protection are critical for extended shelf life.

Cannabis degradation occurs when flower is exposed to air, light, and improper humidity. UV radiation breaks down THC, CBD, and essential terpenes, while oxygen exposure converts THC to CBN (causing sedative effects rather than cerebral effects). Studies show average observed THC potency was 23.1% lower than labeled values due to inadequate packaging protection.

Consider these factors: bud density (indica strains are denser than sativa), desired air space for curing (small amount needed for proper air exchange), moisture content (optimal 10-15%), and whether offering whole buds or pre-ground material. We recommend requesting samples to test-fill volumes before large purchases and consulting our packaging specialists for product-specific recommendations.

Yes, our regulatory compliance team tracks requirements across all cannabis markets, creating packaging systems that maintain brand consistency while addressing state-specific requirements. We provide comprehensive documentation of compliance testing and certification for child-resistant mechanisms, warning symbols, and required packaging features, simplifying audit preparation.