Amber and violet tinted varieties block harmful radiation, preserving cannabinoid potency and terpene profiles throughout storage and retail display.

Cannabis Pre-Rolls

Cannabis pre-rolls represent the ultimate convenience in cannabis consumption, offering ready-to-smoke joints that eliminate the need for grinding, rolling, or packing. These professionally crafted products provide consistent dosing and quality, making them ideal for both novice consumers and experienced enthusiasts seeking hassle-free cannabis enjoyment.

Structural Fragility

Size Variations

Moisture Sensitivity

Aroma Containment

Multi-Pack Configurations

Infusion Considerations

From Manufacturing to Market

Advanced Cannabis Pre-Roll Packaging Solutions

Requirement:

Pre-rolls are highly susceptible to structural damage from crushing forces and bending stress during transportation, handling, and retail display. Even minor deformation can cause paper tears, loose cannabis spillage, and uneven burning that renders products unsellable and creates customer dissatisfaction.

Ghettopac Solution:

Rigid tube construction with precise internal diameter tolerances that cradle pre-rolls without compression. Our containers feature reinforced sidewalls, protective end caps, and shock-absorbing materials that distribute impact forces away from the delicate pre-roll structure, ensuring products arrive intact and ready for consumption.

Requirement:

Cannabis pre-rolls require optimal moisture content between 10-12% and controlled airflow to ensure even burning, proper ash formation, and consistent draw resistance. Improper humidity levels cause harsh smoking experiences, canoeing, and frequent relighting that diminish product quality.

Ghettopac Solution:

Airtight sealing systems with integrated humidity regulation chambers for moisture control packets. Our tube designs feature vapor barriers that maintain optimal internal conditions while preventing moisture infiltration during storage and transport.

Requirement:

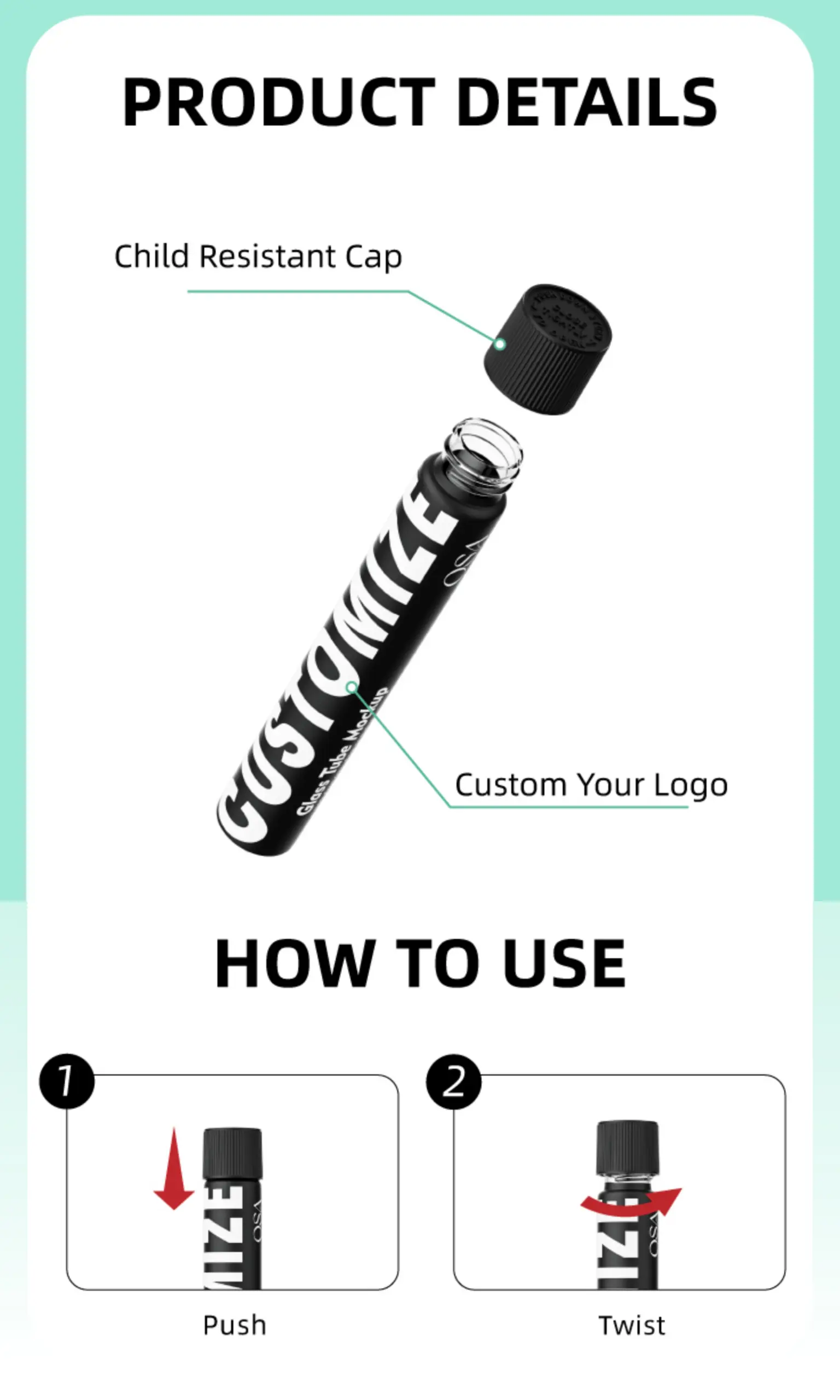

Pre-roll tubes must incorporate child-resistant mechanisms suitable for cylindrical packaging formats while maintaining single-handed operation for adult consumers. Standard push-and-turn caps must function reliably despite repeated use and various environmental conditions.

Ghettopac Solution:

ASTM D3475-certified push-and-turn closures specifically engineered for tube applications, featuring precise threading tolerances and tactile alignment indicators. Our designs include squeeze-to-release mechanisms and multi-directional push systems that prevent accidental opening while ensuring consistent adult accessibility across hundreds of use cycles.

Requirement:

Pre-rolls contain concentrated cannabis flower in confined spaces, creating intense aromatic compounds that must be completely contained to prevent detection, comply with public consumption laws, and maintain product discretion during transport and storage.

Ghettopac Solution:

Multi-layer barrier technology featuring activated carbon filters integrated into cap designs and hermetic sealing systems with silicone gaskets. Our odor-proof containers utilize molecular barrier films that prevent terpene migration while preserving aromatic intensity within the package for optimal consumer experience upon opening.

Requirement:

Cylindrical pre-roll tubes provide minimal surface area for mandatory compliance information including potency data, warning statements, batch tracking, and regulatory symbols while maintaining readable font sizes and proper warning placement according to state requirements.

Ghettopac Solution:

Wraparound labeling systems with variable data printing capabilities that maximize information density without compromising readability. Our templates ensure compliant font sizing, warning prominence, and tracking code integration while utilizing innovative label shapes and clear viewing windows that optimize space utilization on curved surfaces.

Requirement:

Pre-roll packaging must capture consumer attention in crowded dispensary display cases while communicating product quality, potency, and brand values within seconds of visual contact. Competitive differentiation is critical for driving purchase decisions in saturated markets.

Ghettopac Solution:

Premium finishing techniques including soft-touch coatings, holographic elements, embossed textures, and LED-compatible translucent materials that create memorable shelf presence. Our custom color-matching and unique structural designs ensure brand recognition while highlighting product quality indicators that influence consumer selection.

Requirement:

Pre-roll consumption patterns vary from single-session use to partial consumption requiring re-storage, demanding packaging that maintains product quality for both immediate use and extended storage after initial opening while preserving freshness and preventing contamination.

Ghettopac Solution:

Dual-function closure systems featuring initial tamper-evidence for compliance followed by reliable resealing capability for extended storage. Our designs incorporate freshness indicators, reseal-strength testing, and airtight performance maintenance that protects partially consumed products while meeting regulatory requirements for unopened merchandise.

FAQ

What are the standard pre-roll sizes and packaging dimensions?

The most popular pre-roll size is 1 gram (63% of brands), followed by 0.5 gram (43% of brands). Standard tube lengths include 70mm, 84mm, 98mm, and 116mm to accommodate different pre-roll sizes and tip lengths. Multi-packs require larger containers with internal dividers to prevent product contact.

How do child-resistant requirements differ for pre-rolls vs. flower?

Pre-roll packaging must meet the same ASTM standards as flower packaging, requiring mechanisms difficult for children under five to open within a reasonable timeframe. However, pre-roll tubes often use push-and-turn caps or squeeze-and-pull mechanisms, while some multi-packs can achieve compliance through sealed outer pouches.

What labeling information is mandatory for pre-roll packaging?

Required labeling typically includes THC/CBD content, net weight, harvest date, batch numbers, testing lab information, government warning statements, and unique tracking identifiers. Font sizes, warning placement, and specific language requirements vary by state, making compliance templates essential for multi-state operations.

How can packaging prevent pre-roll damage during shipping?

Proper packaging prevents crushing through rigid container walls, shock-absorbing materials, and precise internal fitting that eliminates movement. Glass tubes offer superior protection but require careful shipping consideration, while impact-resistant plastic provides durability with lighter weight for shipping cost savings.

What's the difference between stock and custom pre-roll packaging?

Stock packaging offers lower minimums, shorter lead times, and immediate availability with custom label application. Custom packaging provides unlimited design flexibility and perfect product fitting but requires higher minimums and longer production times. Many brands combine stock containers with custom labels for optimal balance.

How do humidity control requirements work for pre-rolls?

Pre-rolls require 55-62% relative humidity to maintain quality without mold risk. Packaging should include designated spaces for two-way humidity control packets and airtight sealing to maintain consistent internal conditions. Multi-packs especially benefit from humidity regulation due to longer storage periods.

Are there eco-friendly options for pre-roll packaging?

Yes, sustainable options include biodegradable tubes, recycled paper multi-packs, and compostable materials. Some states like New Mexico require compostable or recyclable packaging materials, while Vermont mandates reusable, non-plastic options, making eco-friendly packaging both environmentally responsible and compliance-necessary.

How does infused pre-roll packaging differ from regular flower pre-rolls?

Infused pre-rolls (41% of market) often require premium packaging to justify higher price points. This typically means glass tubes, luxury finishes, and enhanced branding elements. Some infused products may also require additional stability considerations for concentrates and specialized labeling for multiple cannabis ingredients.

How do you choose a reliable cannabis packaging manufacturer?

Selecting the right packaging manufacturer requires evaluating several key factors. First, verify their cannabis industry expertise. Ensure they demonstrate current compliance knowledge of child-resistant requirements, state regulations, and ASTM standards across different jurisdictions.

Assess their quality control processes including material testing, certifications, and inspection procedures. Evaluate customization capabilities such as printing options, material variety, and flexible minimum orders to accommodate your growth.