Superior UV protection from color coatings and tinted finishes preserves cannabinoid potency while delivering a professional, high-end look that supports premium pricing for top-quality cannabis extracts.

Cannabis Tinctures & Oils

Cannabis tinctures and oils represent precision-dosed liquid cannabis products that deliver consistent therapeutic effects through sublingual or oral administration. These concentrated extracts contain higher cannabinoid levels than edible products, with tinctures permitted up to 1,000mg THC compared to 100mg limits for edibles. Professional packaging ensures accurate dosing, product stability, and regulatory compliance while providing convenient, discrete consumption methods for both medical and recreational users.

Light Sensitivity and UV Protection

Temperature Sensitivity and Heat Exposure

Child Safety Compliance

Precise Dosing Requirements

Volume and Potency Regulations

Product Stability and Contamination

From Manufacturing to Market

Advanced Cannabis Tincture and Oil Packaging Solutions

Requirement:

State regulations mandate comprehensive batch tracking and quality documentation throughout the manufacturing process. Each container must be traceable from production through retail sale, requiring packaging systems that accommodate serialized labeling and compliance documentation.

Ghettopac Solution:

Integrated quality control packaging featuring serialized bottle coding, batch tracking labels, and compliance documentation systems. Our packaging includes tamper-evident features with unique batch identifiers that enable complete supply chain traceability while meeting state-specific documentation requirements for inventory tracking systems.

Requirement:

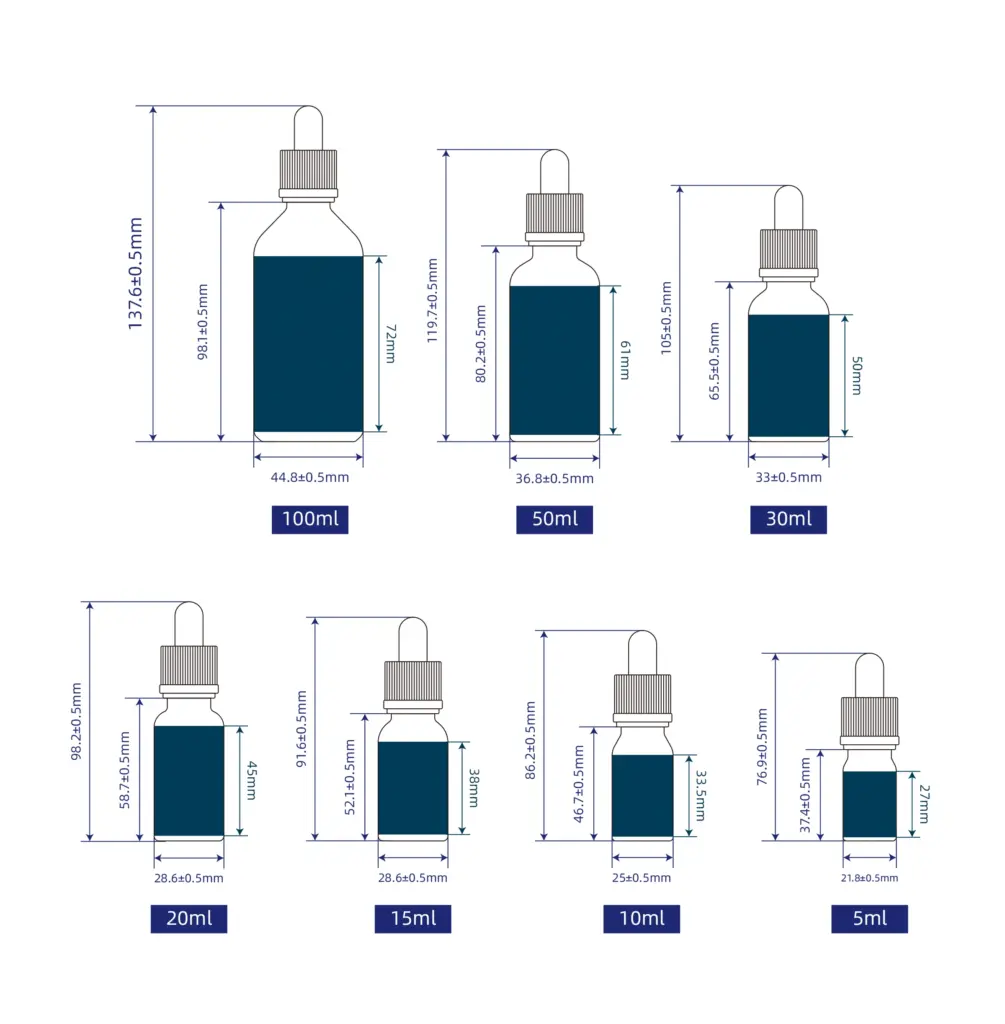

State regulations mandate specific volume limitations and ingredient restrictions for cannabis tinctures to maintain product category distinction from edible beverages, requiring precise container sizing and compliance documentation.

Ghettopac Solution:

Complete regulatory compliance packaging systems with pre-certified volume specifications and documentation packages. Our tincture bottles meet state-specific requirements across multiple jurisdictions, with volume options ranging from 5ml to 100ml and compliance certification for streamlined approval processes.

Requirement:

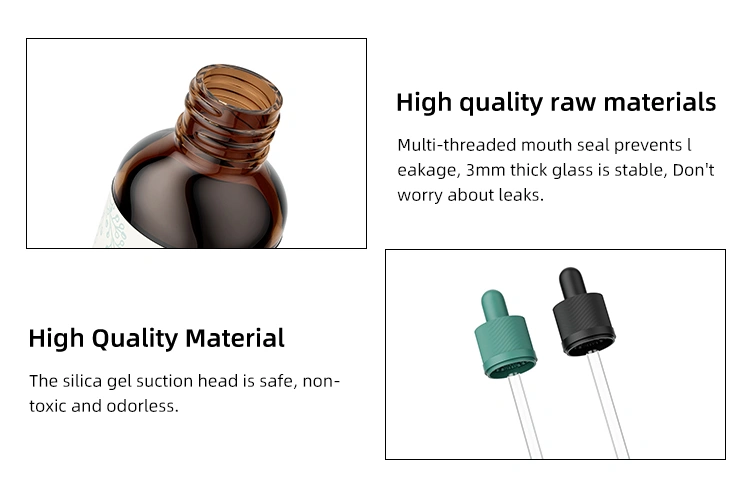

Cannabis oil packaging must incorporate child-resistant mechanisms suitable for liquid-filled bottles while maintaining easy adult access for repeated daily dosing, especially for medical cannabis patients with limited dexterity.

Ghettopac Solution:

Specialized child-resistant dropper caps featuring dual-action safety mechanisms and ergonomic design principles. Our CR droppers require coordinated pushing and turning motions difficult for children under five while providing single-handed operation for adult consumers, including those with arthritis or mobility limitations.

Requirement:

Cannabis tinctures and oils contain light-sensitive cannabinoids and terpenes that rapidly degrade under UV exposure, losing potency and developing off-flavors that diminish therapeutic effectiveness and consumer satisfaction.

Ghettopac Solution:

Amber and violet glass bottles with UV-blocking properties that filter harmful light wavelengths while maintaining product visibility. Our specialized glass formulations provide superior protection compared to standard amber glass, preserving cannabinoid profiles and extending shelf life for premium cannabis extracts.

Requirement:

Liquid cannabis products require precise dosing mechanisms to ensure consistent cannabinoid delivery, as measurement errors can lead to ineffective therapy or adverse effects due to high potency concentrations exceeding 1,000mg THC per container.

Ghettopac Solution:

Integrated graduated droppers and precision dosing syringes that deliver accurate measurements from 0.25ml to 2ml serving sizes. Our calibrated measuring devices meet state regulatory requirements while providing intuitive dosing guidance for both novice and experienced consumers.

Requirement:

Cannabis oils require contamination-free storage environments that prevent oxidation, microbial growth, and moisture infiltration while maintaining product potency throughout extended storage periods and repeated container opening.

Ghettopac Solution:

Hermetic sealing systems with inert gas flushing capabilities and moisture barrier technology. Our advanced closure designs feature silicone gaskets and specialized threading that maintain airtight seals through hundreds of use cycles while preventing contamination and preserving product freshness.

Requirement:

Cannabis tincture packaging must accommodate high-density information requirements including cannabinoid content, dosing instructions, batch tracking, and regulatory warnings while maintaining readability on small-format containers.

Ghettopac Solution:

Multi-panel labeling systems and wraparound label applications that maximize information density without compromising regulatory compliance. Our label templates ensure proper font sizing, warning prominence, and QR code integration for digital compliance tracking while maintaining professional aesthetic appeal.

Requirement:

High-end cannabis tinctures require sophisticated packaging that justifies premium pricing while differentiating from lower-tier competitors. Luxury cannabis markets demand packaging that communicates quality, purity, and therapeutic effectiveness through visual and tactile design elements.

Ghettopac Solution:

Luxury finishing techniques including soft-touch coatings, embossed brand elements, custom color-matching, and unique structural designs that create memorable shelf presence. Our premium packaging options feature specialized printing techniques, metallic accents, and textured surfaces that enhance perceived value and drive consumer preference. Custom dropper designs and ergonomic bottle shapes provide distinctive brand identity while maintaining functional excellence.

Legal Compliance Essentials for Cannabis Tincture & Oil Packaging

Child-Resistant Closures

-

All states that allow cannabis sales require push-and-turn or squeeze-and-turn caps certified to ASTM/Poison Prevention standards.

-

California, Colorado, Massachusetts, and Maryland explicitly fine or recall products lacking CR functionality.

-

Tamper-Evident Integrity

-

A visible safety indicator—shrink band, break-off ring, or perforated seal—must show first-use access.

-

Most regulators treat the absence of tamper evidence as “adulterated packaging,” triggering mandatory product holds.

-

Labeling Essentials

-

Primary panel (front) must list net volume, THC/CBD per serving, universal cannabis symbol, and required health warnings in ≥6-point font (California) or state-specified size.

-

Informational panel includes ingredient list, batch/lot, manufacture date, expiration, and licensee number.

-

QR codes linking to third-party lab COAs are now mandatory in several newer markets (e.g., New Jersey), and strongly advised elsewhere.

-

Prohibited Marketing Elements

-

No cartoons, candy imagery, or child-appealing fonts/colors.

-

Banned claims: “organic” without certification, unverifiable health benefits, or references that mimic alcoholic beverages (e.g., “cannabis whiskey”).

-

Material & Visibility Rules

-

Edibles must be in opaque containers; tinctures and oils may use clear glass only if outer packaging or label obscures cannabinoid liquids from open view in California and Colorado.

-

All resealable packages holding multiple doses must stay child-resistant after first opening—resealable mylar bags alone are insufficient for liquids.

-

Serving-Measurement Devices

-

If a bottle lacks printed graduation marks, a separate dosing syringe, cup, or calibrated dropper must be included to satisfy “individual-serving indication” clauses in states such as South Dakota and Maryland.

-

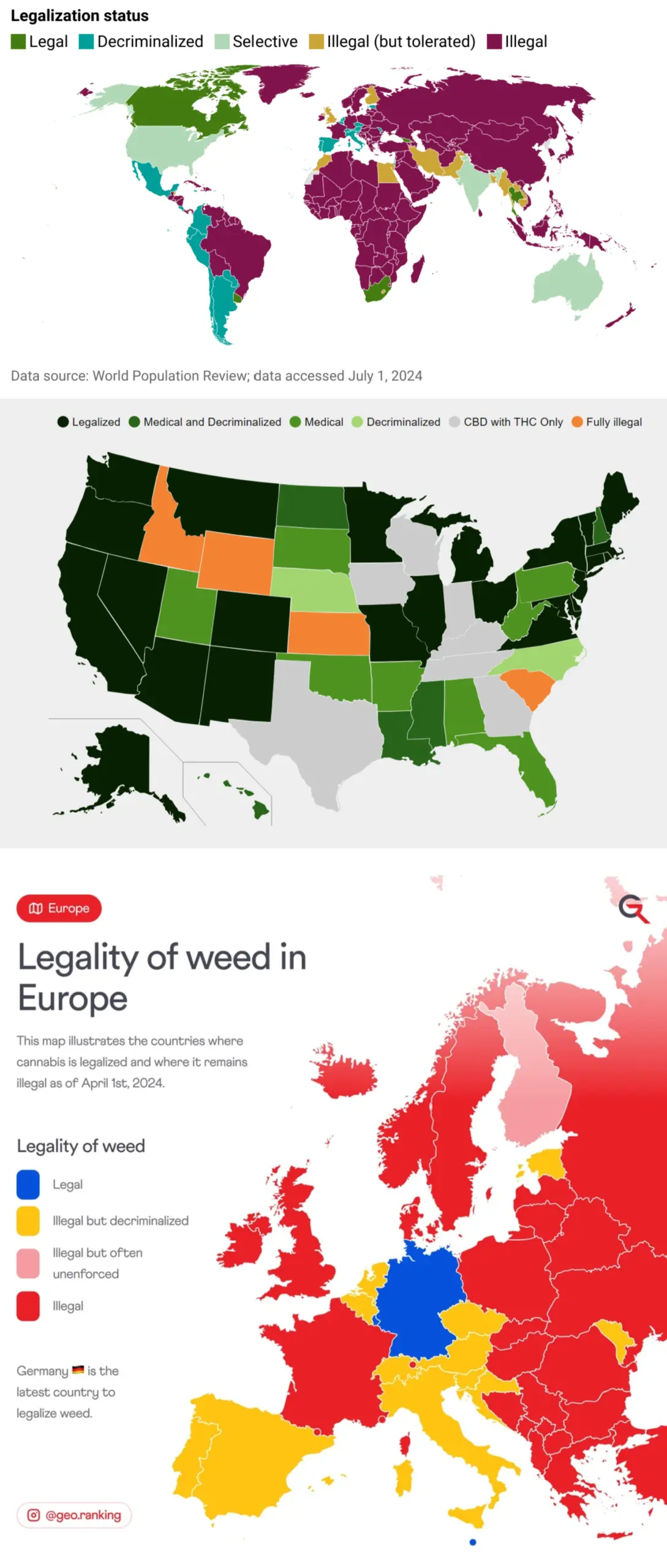

State-by-State Nuances

-

California: Universal symbol ≥0.5 in²; strict 2-tier label (Primary vs. Informational); clear or colored glass now allowed for beverages but not tinctures without an opaque sleeve.

-

Colorado: Requires “contains marijuana” in bold, red font; mandates opacity for products over 10 mg THC per serving.

-

Canada (federal): THC “stop sign” icon, bilingual English/French text, and 10-mg THC cap per non-medical dose.

-

Record-Keeping & Traceability

-

Licensees must retain packaging proofs and label revisions for at least 2 years (California) or as otherwise specified, to present during inspections or product recalls.

-

Batch numbers on both bottle and outer carton tie directly to track-and-trace systems (e.g., Metrc).

-

Environmental & Sustainability Considerations

-

Several states incentivize recyclable glass and restrict excessive packaging; New York’s 2025 rules will require 25% post-consumer recyclate by weight in primary containers.

-

Compostable or hemp-fiber boxes are permitted if they meet child-resistant and tamper-evident standards.

-

Penalties for Non-Compliance

-

Violations range from warning letters and shelf holds to product destruction and five-figure fines. Repeat offenses jeopardize license renewals and may trigger mandatory recalls.

-

FAQ

What are standard tincture bottle sizes and volume regulations?

Cannabis tinctures typically range from 10ml to 100ml volumes, with 15ml, 30ml, and 50ml being most common. State regulations vary significantly – California limits tincture volumes to maintain distinction from beverages, while other states may have different restrictions. Volume limitations help ensure tinctures remain concentrated cannabis products rather than diluted beverages.

How do child-resistant requirements differ for tinctures vs. other products?

Tincture packaging must meet identical ASTM D3475 standards as other cannabis products, but liquid-specific mechanisms are required. Child-resistant dropper caps and push-and-turn vials mechanisms are common solutions. Some states allow secondary child-resistant pouches for additional safety compliance.

Why is UV protection critical for cannabis oil packaging?

Cannabis oils contain light-sensitive cannabinoids and terpenes that degrade under UV exposure, reducing potency and creating off-flavors. Amber glass provides superior protection compared to clear containers, while violet glass offers even greater UV filtering capabilities for premium products requiring maximum preservation.

How do tincture labeling requirements compare to other cannabis products?

Tincture labels must include all standard cannabis information plus specific liquid product requirements: total cannabinoid content per container, serving size cannabinoid content, measuring instructions, and volume specifications. Font size requirements often increase to 8-10 point for cannabis products compared to 6-point for dietary supplements.

What's the difference between medical and recreational tincture packaging?

Medical cannabis tinctures may have different potency limits, require additional therapeutic information, and sometimes allow larger volume containers. Recreational products typically have stricter potency limitations and require more prominent warning statements. Packaging design restrictions may also differ regarding appeal to minors.

Are there eco-friendly options for cannabis tincture packaging?

Sustainable options include recycled glass bottles, biodegradable secondary packaging, and refillable container programs. Some states like Vermont mandate reusable or recyclable packaging materials. Glass bottles inherently offer better recyclability than plastic alternatives while providing superior product protection.

How do infused oil products differ from standard tinctures in packaging needs?

Cannabis oils with additional ingredients may require specialized storage conditions, different labeling for multiple components, and enhanced stability packaging. Products containing both cannabis and other botanical extracts often need premium packaging to justify higher price points and communicate quality positioning.

What factors should guide tincture packaging manufacturer selection?

Evaluate manufacturers based on cannabis-specific expertise, regulatory compliance knowledge across multiple states, quality certifications, and experience with liquid product challenges. Assess their capabilities in child-resistant mechanisms, UV protection options, dosing accuracy, and customization flexibility for branding while ensuring they understand the unique requirements of cannabis tincture packaging.